News

Guardian Multi-View Stereo Vision Measurement System: A Technological Breakthrough in Part Inspection

Time : 2026-01-05

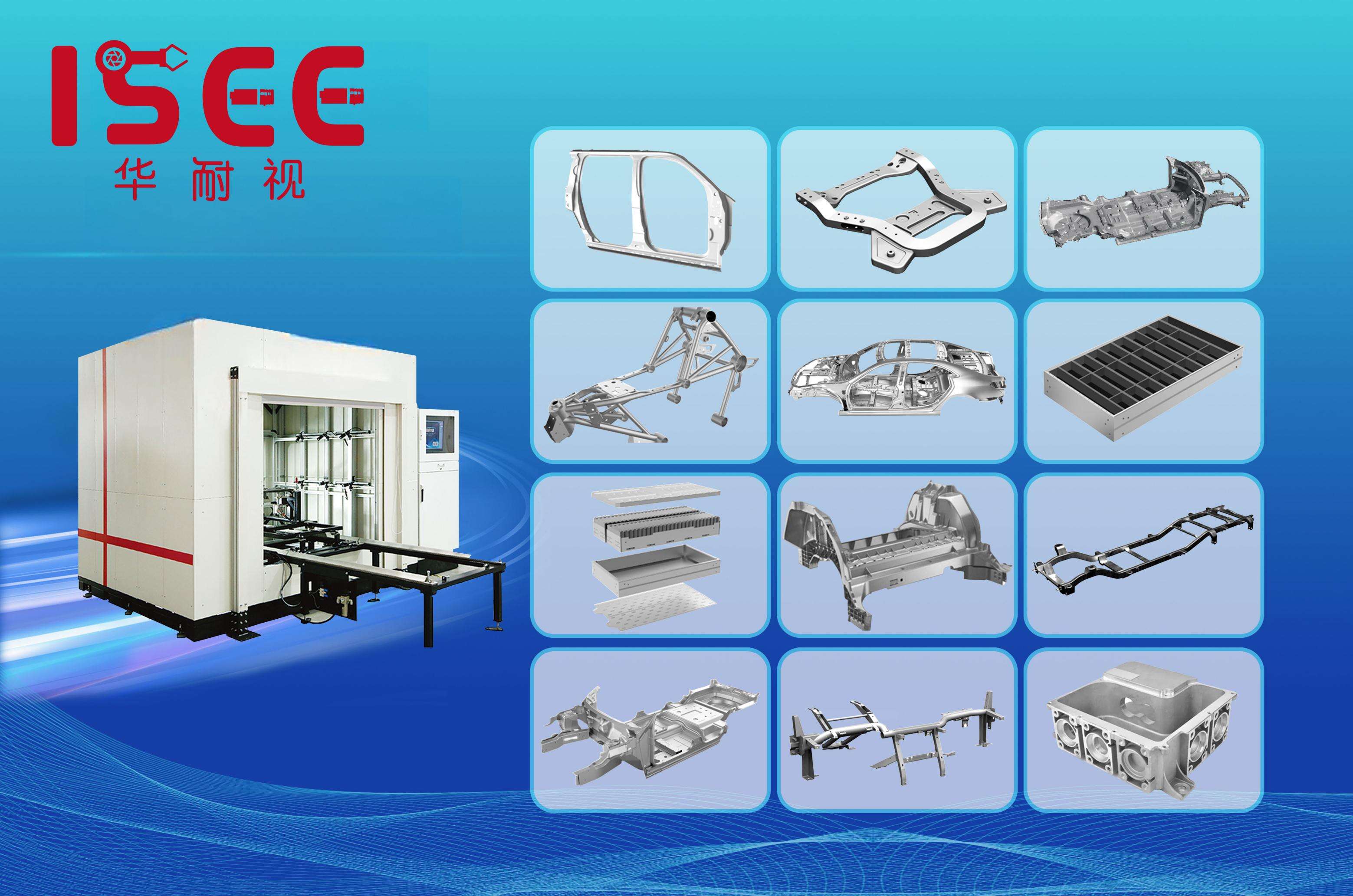

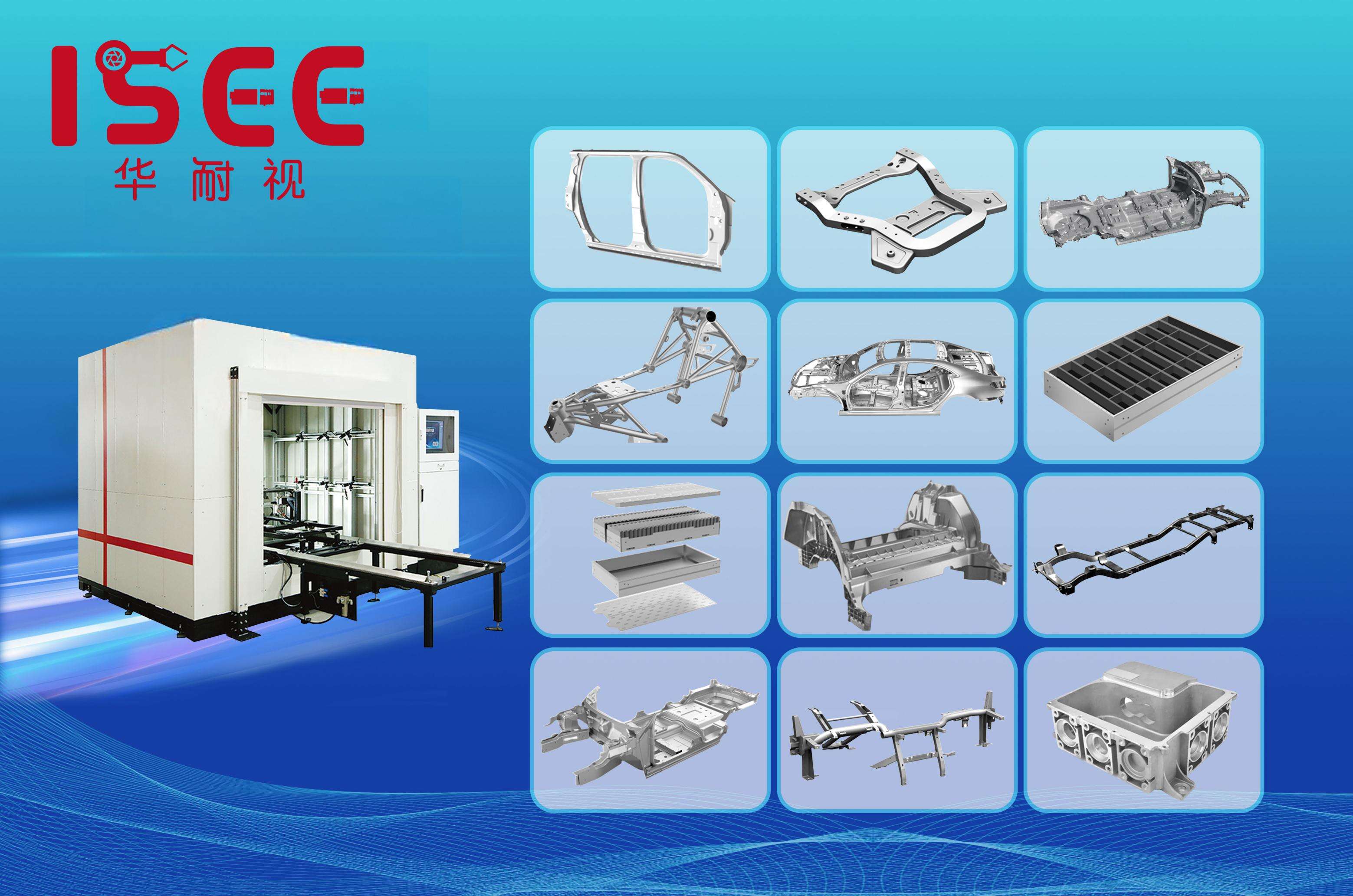

Amid the wave of intelligent transformation in industrial manufacturing, part inspection—an essential process for ensuring product quality and improving production efficiency—has long been constrained by the limitations of traditional inspection methods. Jointly developed by Big Bird Industry, ISEE, and Harbin Institute of Technology, the “Guardian Orient See” Multi-View Stereo Vision Measurement System redefines the logic of part measurement through breakthrough technologies, delivering a revolutionary solution for industrial inspection.

The system’s core advantage lies in its innovative multi-view stereo measurement architecture. Integrating 20 to 40 industrial cameras into a unified measurement network, each inspection point is redundantly measured by three to four cameras simultaneously, forming a highly stable and reliable inspection system. Even if a single camera fails, the remaining cameras continue data computation without interruption, effectively preventing production line downtime and ensuring continuous operation. This multi-camera collaborative approach overturns the inefficiencies of traditional binocular structured light or sequential laser sensor inspection, achieving significant improvements in both efficiency and system stability.

In terms of measurement accuracy, the system incorporates multiple cutting-edge technologies to deliver exceptional precision. By adopting a sub-pixel feature matching algorithm based on grayscale image information, it overcomes the pixel-level limitations of conventional binary matching, improving point matching accuracy to 0.2 pixels. The object-side resolution reaches below 0.02 mm, achieving a final measurement accuracy of ±0.1 mm and a repeatability of ±0.02 mm, with a repeatability σ value as low as 0.007 mm. Through global calibration using high-precision planar calibration boards and more than 100 calibration positions, all camera spatial parameters are solved simultaneously to establish a unified three-dimensional coordinate system, ensuring consistent measurement references. To counteract environmental influences that may cause camera pose drift, the system embeds numerous reference targets and automatically corrects minor deviations during each measurement, maintaining long-term accuracy stability.

The system also delivers major breakthroughs in functional adaptability and inspection efficiency. Centered on position tolerance measurement, it flexibly supports the inspection of hole positions, missing components, gap distances, and more, adapting to diverse applications such as automotive chassis, body components, and large industrial parts. Two product series—S and M—are available to accommodate parts with maximum lengths of 1,800 mm and 5,000 mm respectively. The system supports robotic handling, conveyor loading and unloading, as well as manual operation, with equipment dimensions customizable to on-site production layouts. Most importantly, it achieves high-efficiency inspection within 10 to 30 seconds per part, realizing a true “dual 100%” inspection standard—100% product coverage on the production line and 100% feature coverage at all inspection points. This completely replaces traditional manual gauges and coordinate measuring machine (CMM) sampling methods, while avoiding the long cycle times and wear issues associated with single-vision inspection systems.

Backed by the technical teams of ISEE and Harbin Institute of Technology, the system deeply integrates cutting-edge academic research with real-world industrial demands. The core R&D team, led by professors and PhDs in pattern recognition and intelligent systems, has overcome key challenges such as multi-camera collaboration and high-precision calibration through profound technical expertise. Its technological achievements have been recognized and supported by the Heilongjiang Provincial Department of Science and Technology and the Department of Industry and Information Technology.

With multi-view collaboration, high-precision algorithms, and intelligent adaptability at its core, the Guardian Multi-View Stereo Vision Measurement System not only addresses the longstanding challenges of low efficiency, limited accuracy, and insufficient flexibility in traditional inspection, but also provides full-process quality assurance through data traceability and process optimization—emerging as a key enabling technology for high-quality development in modern manufacturing.