News

What Are the Advantages of Die-Cast Parts in Auto Production?

In the auto manufacturing industry, companies are constantly looking for parts that improve efficiency, reduce costs, and improve the performance of the vehicle. Die-cast sections are winning over auto manufacturers for their unique advantages in all three and more. Here’s why they are becoming indispensable in auto manufacturing today.

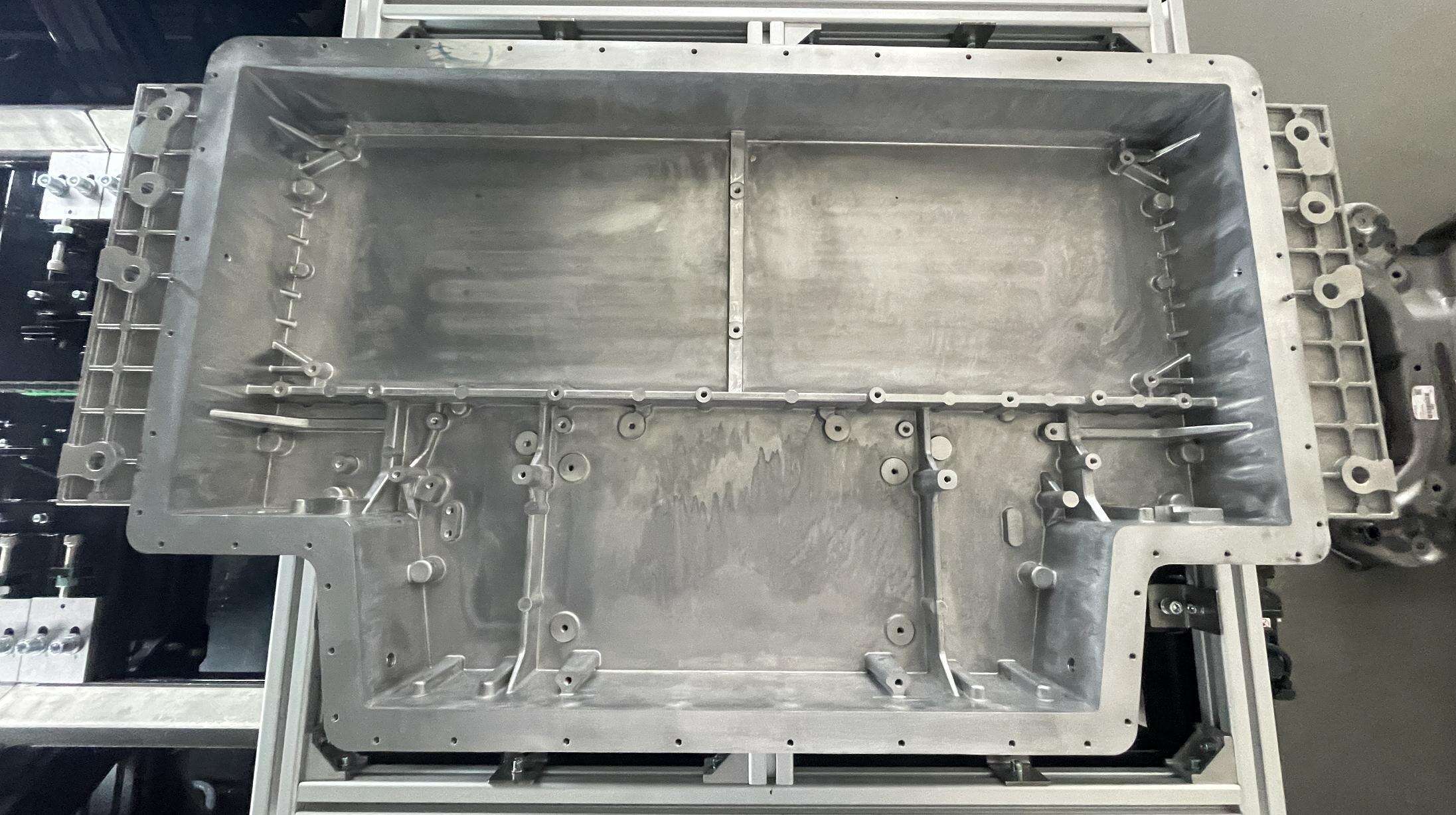

Outstanding Accuracy for Complex Parts of Automobiles

Among the various precision manufacturing techniques, die-casting parts are known for their precision, which is vital in the auto industry for complicated parts and components. This is because the die-casting process involves the construction of metal molds with extreme care and detail. Every component that comes out is uniform and integrates with all the adjoining components of the vehicle. For example, transmission housings and engine brackets are die-cast parts and must be of uniform size and shape, which is critical for their functional operation together. Die-cast parts even limit the additional machining that is required because of the precision and accuracy of the components which in the case of engine brackets saves time and in case of the final vehicle ensures that the entire assembly functions properly.

Lightest Materials but Strongest Alloys

Lightness in vehicle parts means more fuel savings and better performance. For die-cast parts, lightness and strength are achieved through aluminum and magnesium alloys. Compared to steel, alloys are lighter and strong enough to withstand everyday drives. An example of this would be a wheel hub. Fuel savings are achieved by using die-cast wheel hubs, as they are light enough to lower the weight of the vehicle. The wheel hubs die-cast design is also strong and durable enough to support the vehicle's weight and absorb shocks from the road. This balance between lightness and strength is the reason die-cast parts are preferred by automakers. This enhances safety and efficiency.

Cost-Effectiveness of Mass Production

Cost-effectiveness in mass production is of utmost importance in the automotive industry. This is because of the high-speed production process of die-cast components. After the first metal mold is created, die-casting machines can fabricate thousands of components in no time. This production speed drastically reduces the cost of components in a batch. The process is very low waste as any remaining metal is recycled back into the production process. This is beneficial for the environment as well as the cost of production. Die-casting reduces the cost of production while maintaining quality for automakers who produce thousands of vehicles a year. Automakers keep quality production costs low by using die-cast components.

Reducing Post-Processing While Ensuring Excellent Surface Finishes

From a functional and aesthetic standpoint, a smooth surface finish is a must for automotive components – and die-cast parts deliver a near-perfect finish straight off the production line. This is thanks to the precision-engineered smooth metal molds used in the casting process, which impart their sleek texture to the parts during formation. As a result, time-consuming sanding and polishing steps can be eliminated from post-processing. After manufacturing, these parts undergo thorough cleaning and strict quality inspections to ensure only defect-free products leave the factory, further safeguarding their reliability. A smooth surface not only boosts the visual appeal of visible components like interior trim but also benefits hidden parts: it minimizes friction and wear, extending the component’s service life. For automakers, this translates to greater value – less post-processing work, components that are ready for immediate installation, and consistent quality you can trust.

Flexibility in Design to Cater to Auto Needs in All Dimensions

Flexibility in design allows businesses to respond to customer’s unique and evolving requirements in manufacturing and automotive technologies. Regardless of the shape and complexity of the design, die-cast components can be manufactured. Since die-casting can manage elaborate designs, automotive manufacturers can exercise creativity, specifically in enhancing the aerodynamics and contouring the body of the car. Consider the scenario when an automotive part’s die-cast design encompasses multiple functionalities. This consolidation lessens the part count and eases the assembly process for the manufacturer. The ability to functionally integrate components is one distinct reason die-cast parts become an integral manufacturing technology in the automotive market.

There’s no doubt die-cast components can be used in the design automotive parts. The automotive sector can build components faster and more efficiently when they die-cast. The option to use die-cast parts will increase the flexibility in the design enabling the manufacturers to build quality cars and assist more efficient vehicle production.