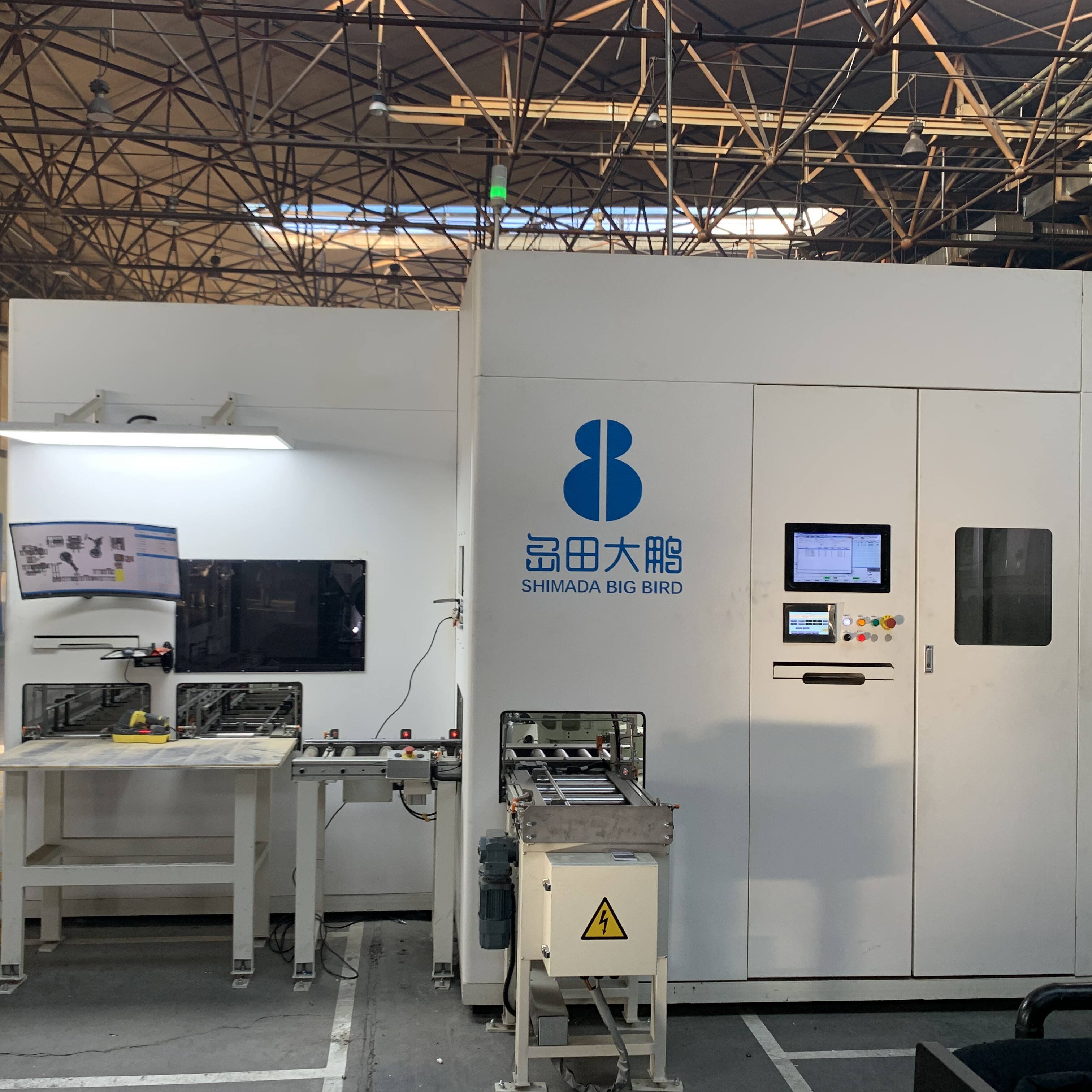

Surface See - Defect Vision Inspection System

This example for Cylinder Head Defect Vision Inspection System

Production Cycle: 36s (customizable based on workpiece)

Industrial Cameras: 5–25 MP (48 units)

Lighting: Surface light, combined strip lighting

Control System: Industrial PC, PLC

Laser Profilometer: Detection accuracy ±0.1mm

Description

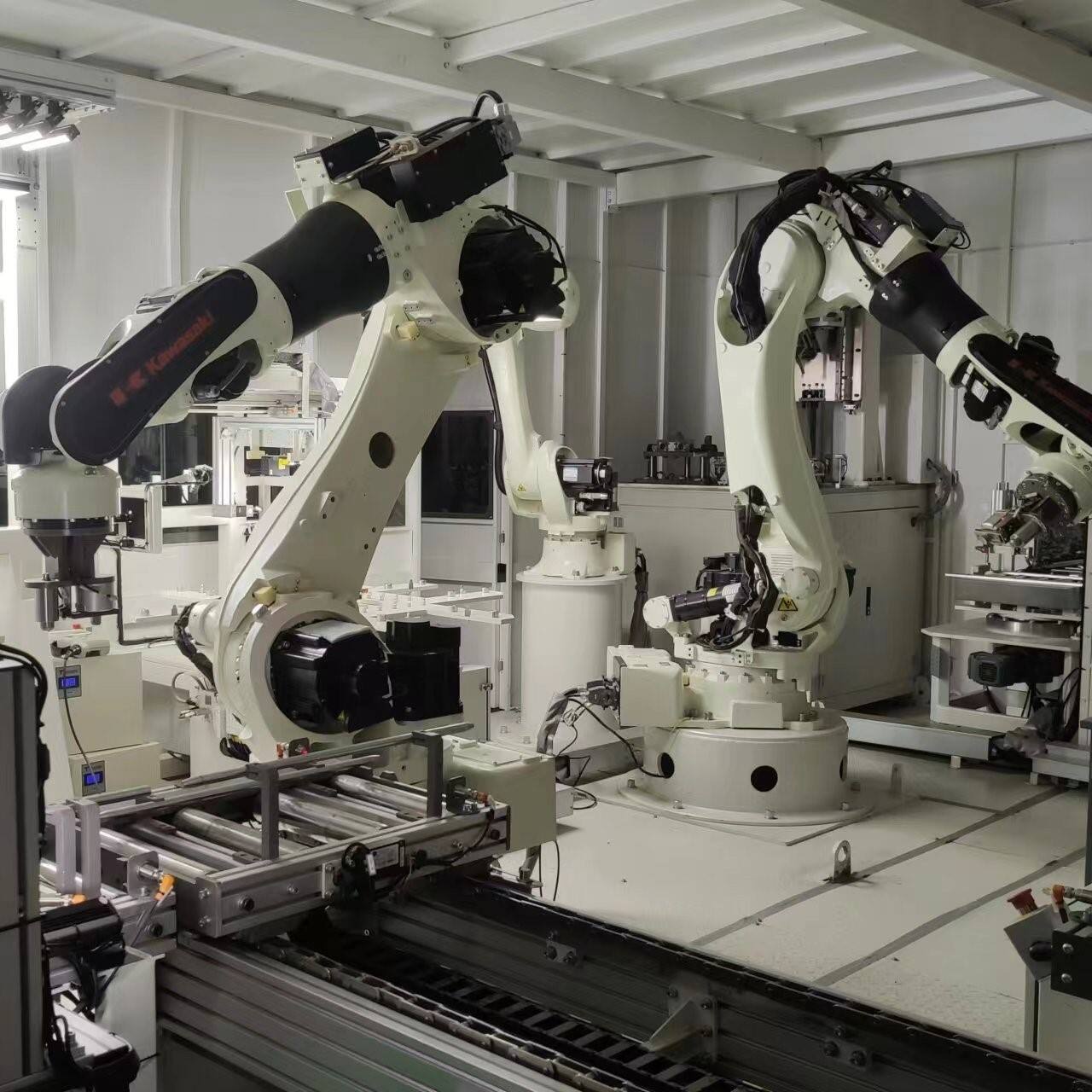

Master - Defect Vision Inspection System

This example for Cylinder Head Defect Vision Inspection System

Technical Specifications

| Specification Item | Details |

|---|---|

| Production Cycle | 36s (customizable based on workpiece) |

| Industrial Cameras | 5–25 MP (48 units) |

| Lighting | Surface light, combined strip lighting |

| Control System | Industrial PC, PLC |

| Laser Profilometer | Detection accuracy ±0.1mm |

Note: Specifications are for reference only. For more details, please contact us.

Applicable Industries

Commercial vehicles, passenger vehicles (including new energy vehicles).

Supported Workpieces

Engine cylinder heads.

Equipment Description

The system provides automated recognition, marking, key dimension inspection, defect detection, qualified marking, and information binding/storage for various cylinder head models. It replaces traditional manual inspection, significantly improving automation, reducing labor costs, and minimizing missed detections.

Process Overview

Deburring of combustion chamber

Cylinder head recognition & marking

Cover & intake surface defect inspection

3D dimensional inspection

Combustion chamber & exhaust surface defect inspection

Front & rear surface defect inspection

Machined dimension inspection

For NG cases:

Manual re-inspection

Defect Detection

Covers both machined and raw surfaces, including:

Sand holes, air holes, sand block residues

Core breaks, mold misalignment, burn marks

Collisions, scratches, and other surface defects

Dimensional Measurement

Combustion chamber volume

Intake and exhaust port volume (indirect measurement)