Paint Surface Inspection System

In the same beat cycle, the online automated robot guidance system is used to inspect the body paint surfaces of all color series. It achieves metrological-level accuracy, realizes objective and consistent paint surface inspection, and eliminates human errors. It directly reduces production costs by minimizing manual inspection and optimizes production processes to cut costs through reliable statistical data. The marking robot accurately marks defect locations, simplifying rework and repair work. In the future, robot guidance can replace manual labor to achieve automatic defect repair.

Description

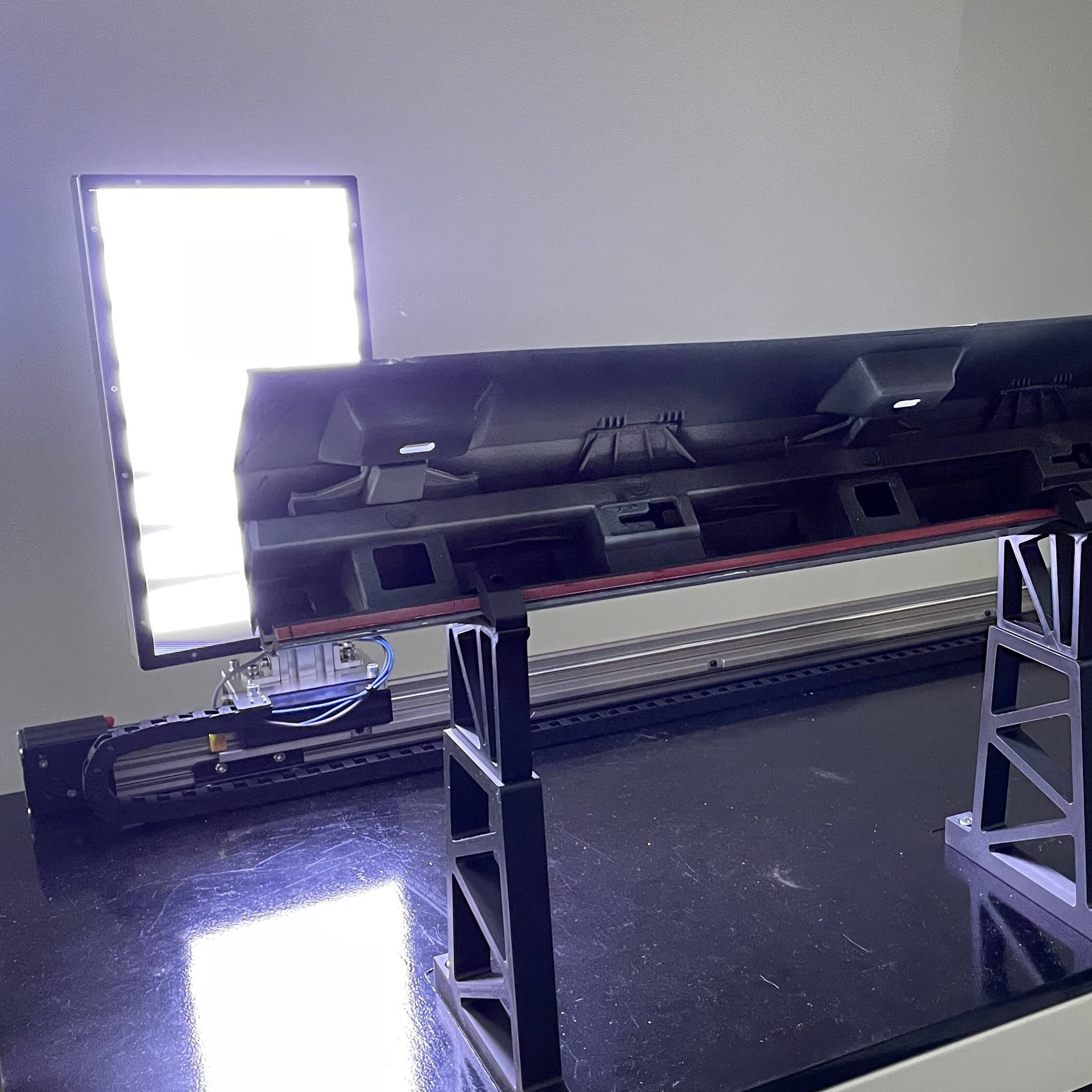

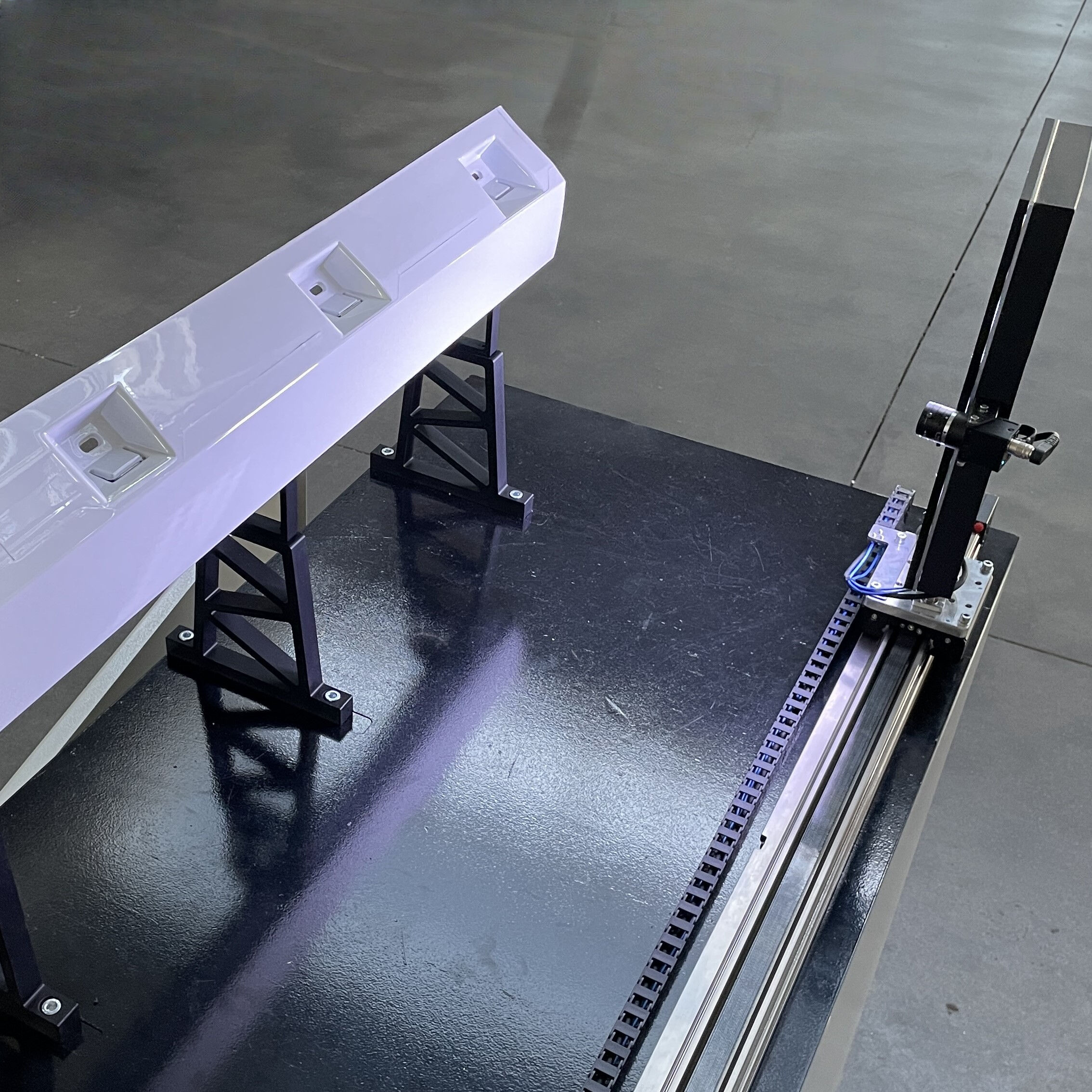

PAINTSCAN - A New Hybrid Technology

Through embedded modules, two surface inspection methods are integrated into the same sensor

LED matrix monitor with independent lighting modes

Diffuse light illumination with high optical sensitivity

Digital camera with high resolution and high acquisition frequency (200 Hz)

Camera directly connected to the embedded computer unit

Capable of detecting all paint surface defects related or unrelated to surface shape

Each position on the vehicle body undergoes multiple inspections through up to 10 images

Inspection modes: "Line tracking" or "Stop and go"

Vehicle inspection time: < 50-70 seconds (with 4 robots; specific time depends on the inspected surface)

Note: According to the latest technology, using 7-axis robots can reduce the inspection time to < 40-60 seconds

Automatic Marking System

Visual coordinate system generates paint defect locations

The inspection system calculates coordinates within the vehicle body coordinate system (based on 3D robot path data)

The marking system automatically generates dynamic marking trajectories

Automatic trajectory setting and anti-collision inspection for all defect markings

Each defect marking takes approximately 3 seconds (including robot movement time)

Compatible with robots of all brands