News

Why Is Precision Critical in Crankshaft Manufacturing?

Crankshafts and Their Importance in Vehicles

Crankshafts are automotive engine "power hearts", responsible for changing linear motion of the pistons into the circular motion necessary for propulsion. Even the most minor adjustments in the dimension of a crankshaft such as journal concentricity of 0.01mm precision error can cause uneven force distribution within the crankshaft resulting in engine noise. This uneven force distribution can cause the bearings and other engine parts to wear quicker and in extreme cases shorten the lifetime of the engine by 30%. For the engine to be considered reliable and fuel efficient, the precision of the crankshaft construction must be optimal. This is crucial for the engine performance as a whole.

Issues with Precision and How It May Affect Crankshaft Functionality

The various types of precision defects in crankshafts may comprise issues of surface finish, scale and degree of unevenness of dimensions of main journals and connecting rod journals, as well as warping because of poor heat treatment. For instance, if the crankshaft journal surface finish gets rougher than Ra 0.8μm, the crankshaft journals will have less than the optimal contact area with the bearing, which will cause local overheating. This will cause the bearing seizure after some time, which will require the entire engine to be disassembled and repaired. On the contrary, the displacement of dimensions will generate a fault in the engine compression ratio which will cause a power drop and an increase in fuel consumption. This multiple issues presented, only show the importance of precision in all steps of crankshaft manufacturing, which includes forging, as well as final finishing.

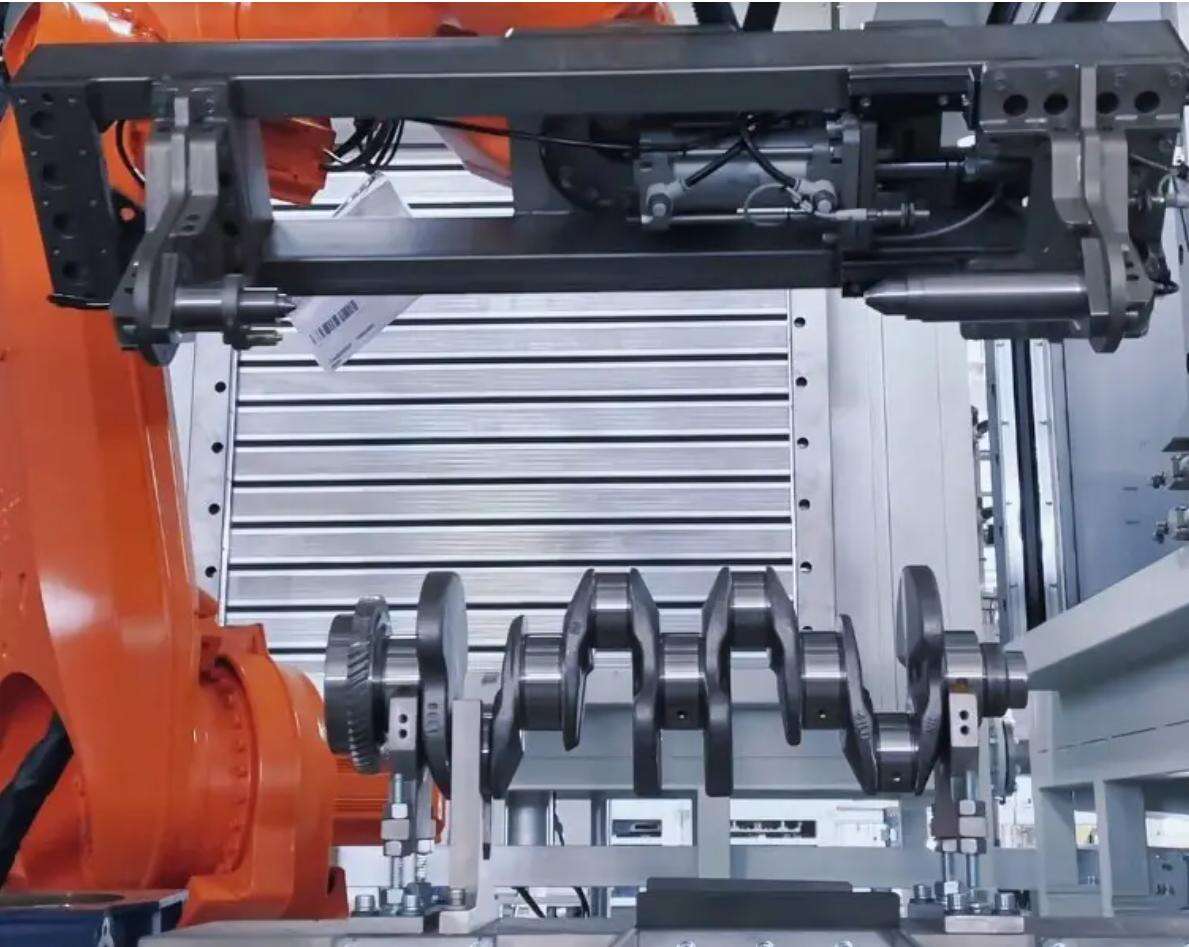

Specialized Equipment Needed in Precison Assurance

In order to maintain the consistency necessary for achieving precision crankshaft production, one needs to invest in specialized manufacturing and inspection equipment. For instance, removing the metal chips, coolant residues and other contaminants from the crankshaft surface and the internal oil passages on industrial precision cleaninghigh-end machines is crucial. Leaving even the tiniest particles on the surface can result in scratches to the most critical areas in the processing steps when the crankshaft is further processed, causing a loss of precision which is most unfortunate. On the inspection side, intelligent visual inspection equipment uses high-resolution cameras and advanced optimisation algorithms. In order to ensure that only crank shafts meeting the most exacting precision requirements are passed to the engine assembly, these tools are able to locate and identify microDefects such as hairline cracks and surface blemishes.

Worldwide Precision Crankshaft Standards

For the crankshaft industry, there are tolerances which may change according to the region and application type, but there are industry standards which are followed worldwide by automotive manufacturers. The International Organization for Standardization (ISO) outlines tolerances for passenger car crankshafts by specifying tolerances of ±0.005mm for the key journal diameters and a surface flatness of 0.002mm per meter and within the respective limits. For heavy-duty trucks, the standards are tighter as the crankshafts operate at higher loads for extended periods. North American and European automakers operate under the Society of Automotive Engines (SAE) standards, whereas Asian automakers operate by the Japan Automobile Manufacturers Association (JAMA). Standards may differ by region but there is one common understanding which is that crankshafts are to be manufactured with the utmost precision.

Long-Term Benefits of Crankshaft Precision

Long-Term Benefits of Crankshaft Precision Manufacturing precision crankshafts has long lasting value for automakers and end users. For automakers, it improves crankshaft production precision, reducing defective parts, and cutting rework costs and production delays. Defective part costs also decline. An automotive manufacturing research center found that automotive production factories with precision control techniques produced defect crankshafts at 25% lower rates. Consumers benefit from production precision too. Crankshafts of precision quality result in engines operating more smoothly with improved fuel economy. Consumers pay thousands less in maintenance costs over the lifetime of the vehicle, and repairs are less frequent. Well aligned components and precise crankshafts improve fuel burning economy lessening emissions and assisting in the reduction of the global carbon footprint.