News

How to Check Camshaft Wear and Tear Effectively?

How Camshaft Wear Effects Engine Performance

Wear to a camshaft can lead to inefficiencies in an engine's performance. Impacts include loss of power, poorly timed valves, and severe engine damage. In both industrial and automotive applications, seeing the indications early can save time and money. Fuel economy, engine durability, and the loudness of the valves are just a few examples of the consequences of camshaft wear. For both manufacturers and maintenance crews, the ability to detect wear is crucial to maintenance and ensuring the equipment is reliable for a long time.

Indicators of Camshaft Wear

Whether it's physical irregularity on the cam shaft or valve operating mechanisms or it's the audible evidence of valve ticking, camshaft operating dysfunction can be a serious threat to the ameliorative purpose of a camshaft. One of the most overt signs of a wearing camshaft is unbalanced rate of metal wear, causing the shaft to be unbalanced and resulting in a continuous, unresolved friction burn and subsequent wear of metal on the valve seat and its holders. It can also be lack of unbalance metal wear on the seat holders, and continuous burn valve operating mechanisms wear. Excessive clearance and valve tap ticking audible evidence can be signs of a wearing camshaft, and will most likely be symptoms of a lacking camshaft causing valve operating friction. Camshaft valves and the seat holders can also suffer from decreased lubrication, foretold by the presence of metal particles in the oil.

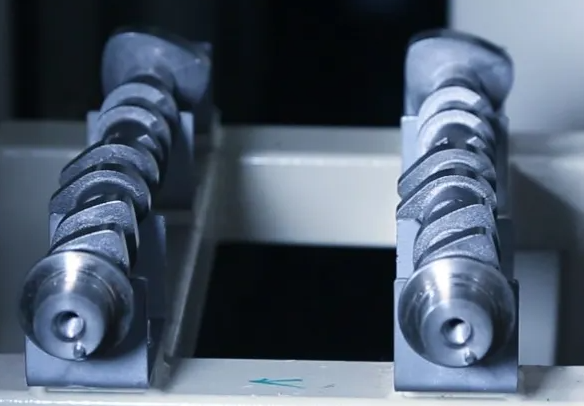

Tools Used for Detailed Wear Measurement

Tools for precise measurement are needed for proper measurement on the camshaft. Important for the measurement of camshaft runout, lobe height, and journal diameter are the dial indicators and micrometers. They help verify the measurements against the manufacturer’s specifications. Advanced inspections may use vision inspection tools which provide measurements accurate to the microns. They can tell if something is missing on the surface. This image is also processed with advanced imaging technology and provides detailed visual data to inform decisions on maintenance and replacement. Automotive and industrial professionals use these instruments for accuracy and consistency.

Step-by-Step Visual Inspection Process

Visual inspection is the first and most important step in successful detection of wear on camshafts. Start when the engine is cool and fully disassembled again to the camshaft level. Inspect all the cam lobes for wear such as rounding and loss of material. Inspect all the journals for too much friction, which is indicated by roughness or scoring. Utilize a flashlight for tight areas and a mirror for surfaces that are hidden. Compare the condition of the camshaft to photos or specifications of the manufacturer to identify discrepancies. This method, in addition to formal training, helps technicians preemptively address potential concerns.

The Use of Updated Inspection Technology

Updated inspection technology helps with identifying camshaft wear faster and in a more efficient way than ever before. Vision inspection systems with multi-view stereo vision are able to look at the camshaft from many different angles, leading to a 3D detailed image that recognizes wear even better than previous systems. These systems measure and evaluate the camshaft condition by stating the depth of the wear as well as the roughness of the surface. These systems, when integrated with production lines, help with identifying any defects at a confidence rate of more than 99%, making them great for industrial usage. Using these updated technologies, manufacturers and maintenance teams can enhance the reliability of overall equipment and streamline inspection processes.

Real World Case of Camshaft Wear Detection

While working on a recent automotive manufacturing project, a team noticed recurring issues with the performance of the engines. After a visual inspection and some measurements, they thought that the root cause of the problems was due to some wear on the camshaft. Using multi-view stereo vision inspection, they discovered some micro-pitting on a few cam lobes that had previously gone undiscovered with classical engineering inspection. The finding of micro-pitting really helped in replacing a camshaft early to prevent further damage to the engine and lost time in the production schedule. This example demonstrates the power of merging classical visual inspections and advanced engineering inspection tools to find wear and stress and the great time and money benefits of proactive maintenance and inspection in stress engineering on product quality.

Linking Engine wear Detection to Long Term Cost Savings

Detecting wear on a camshaft can save a company a lot of money. Business can avoid the high costs to replace or overhaul an engine and save on running costs and spend even less time on the engine. While camshafts can break there are other engines losing money while running the engine that has the broken camshaft. Keeping camshafts good also makes the engine dong the work run better and use less fuel. For a manufacturer to keep the camshafts good makes a more reliable product and gives a better reputation to the company. The need to replace engine parts can be reduced and the company can spend more time on other parts of the business.

Expert Suggestions for Preventive Maintenance

As industry experts point out, preventive maintenance can help reduce the wearing of camshafts. Performing regular oil changes with quality lubricants will help decrease friction, assist the camshaft, and other parts of the engine. Following the manufacturer specifications for maintenance intervals guarantees that the inspections will be done at the right time to identify and remove the wear before it becomes a serious issue. Using quality camshafts and other associated parts will reduce the possibilities of premature wear. Moreover, ensuring that maintenance personnel are trained to use the more sophisticated and updated wear detection tools will help provide more consistent and dependable detection of wear. These practices will allow companies to improve the performance of their tools and diminish failure rates.