News

Why Is Valve Body Calibration Important for Hydraulic Systems?

Understanding What Valves Do in Hydraulic Systems

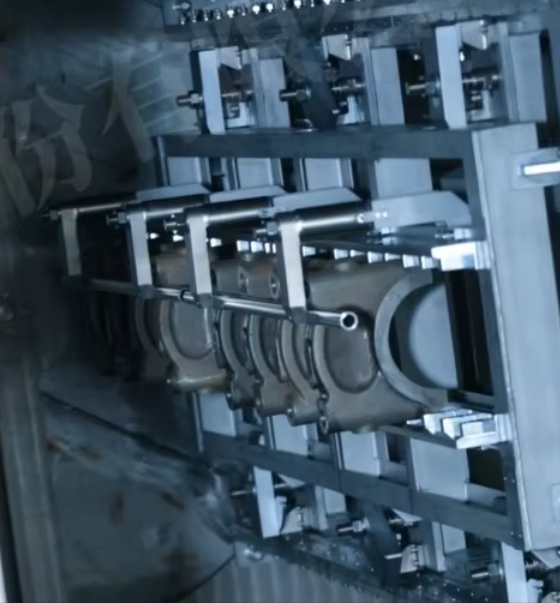

The valve body in hydraulic systems is the brain of the operation. It does the controlling of the oil in the system; how much flows, how much the pressure is, and what direction the oil goes. This provides the needed functions of other components like the cylinders and motors. The reliable functioning of the valve body plays a major role in the efficiency of hydraulic systems, especially in construction, heavy equipment, and automobile manufacturing. A consistently malfunctioning valve body will result in the following: response time increases, energy consumption increases, and oil distribution is uneven. With the right calibration, a valve body can be set to operate at its best and within the standard requirements of the system it is being used in.

Avoiding Expensive System Breakdowns With Proper Calibration

One of the common causes of unexpected downtime in hydraulic systems is miscalibrated valve bodies. In an industrial environment, one system breakdown can stop the entire production line and lead to enormous losses. For instance, in the manufacturing of automotive components, hydraulic systems with miscalibrated valve bodies will produce defective parts which lead to extra costs and delays on rework. Accurate calibration minimizes the chances of breakdowns, leaks, and component failure. Keeping precise performance of valve bodies increases the overall stability of hydraulic systems which reduces the frequency of emergency breakdowns and prolongs the lifetime of essential spare parts. This way of thinking is in line with the cost saving methods global manufacturers employ to improve operational flexibility.

Enhancing Operational Efficiency and Performance

Operational efficiency is driven by how well fluid in hydraulic systems is moved. This allows for improved cycle times and decreased energy usage. Many industrial applications justify the need for small efficiencies for large gains over time. For instance, in assembly line applications, calibrated hydraulic systems work consistently and remove production bottlenecks which increases overall throughput. Additionally, precise hydraulic calibrations enhance overall system performance, which allows the machine controls to respond more to the measured movements. This performance level is vital to industries like automotive and heavy equipment, where even the smallest movements affect product quality and operational safety.

Guiding Industry Standards and Safety Regulations

When it comes to hydraulic systems, particularly in the automotive and heavy machinery sectors, industry professionals and governing bodies offer the most stringent systems. By bringing calibration to the valve body, these standards can be met, avoiding both penalties and legal problems. Safety, too, can not be overlooked. Malfunctioning hydraulic systems, in the case of poor calibration, can be a serious concern to operators, as well as all of the equipment involved. An example of this comes from construction machinery. A valve body that is not properly aligned can lead to a plethora of unexpected actions that can ultimately lead to harm. There are a plethora of steps involved in calibration, as it is governed by a multitude of technical instructions and is ultimately aimed at achieving the desired state of hydraulic systems, all the while meeting the safety and functionality requirements. This leads to the conclusion that all top tier component makers and governing bodies offer the most consistent recommendations towards calibration. This further provides the best industry standard and makes workplaces the most safe.

Proactive Maintenance and Calibration: A Strategy for Long-Term Value

Regular investments in valve body calibrations provide the most validation when it comes to the longevity of hydraulic systems. This is made possible due to improved performance resulting in zero downtime, reduced repair costs, and maximized ROI due to a longer component lifecycle. This is especially true for global enterprises, where systems that are performing consistently contribute to the reliability of the entire supply chain, bolstering customer confidence. Beyond the costs, the hydraulic systems themselves, with calibrated valve bodies, are less likely to require replacements, and fit the increasing demands for systems that create a reduced operational footprint by mitigating waste and optimizing resources. Overall, the operational impact, longevity, and reduced costs justify the initial expense of calibrating as a necessity for any organization.

Leveraging Industry Knowledge for Precision Calibration

Knowledge-based precision calibration is also required for sophisticated tools. Engineering experts in the field of calibration possess cutting-edge tools and the technical knowledge required to measure and fine-tune a valve body's parameters to the micrometer level. Calibration is performed by the best industrial solution providers. They possess engineering expertise for the particular hydraulic system and offer years of engineering experience. They also understand fluid mechanics and offer specialized services for specific system nuisances. By using such industry knowledge, hydraulic systems can be optimized to perform at the level of precision relied upon by the world's automotive and manufacturing companies.

The Real World Impact of Calibration on Industrial Processes

In automobile manufacturing plants, it has been proven that calibrated valve bodies in hydraulic assembly lines increase process consistency which in turn reduces defect rates. One particular case study with heavy machinery operators demonstrated that with regular calibration, unplanned downtime was eliminated by 30 percent, which increased their productivity greatly. These particular examples show how calibration can directly influence operational outcomes. It does not matter if it is in a large scale production facility or a specialized engineering application, the advantages of valve body calibration are both quantifiable and qualitative. For these reasons, businesses should focus on avoiding system inefficiencies by incorporating this maintenance step in order to remain competitive in their industry.