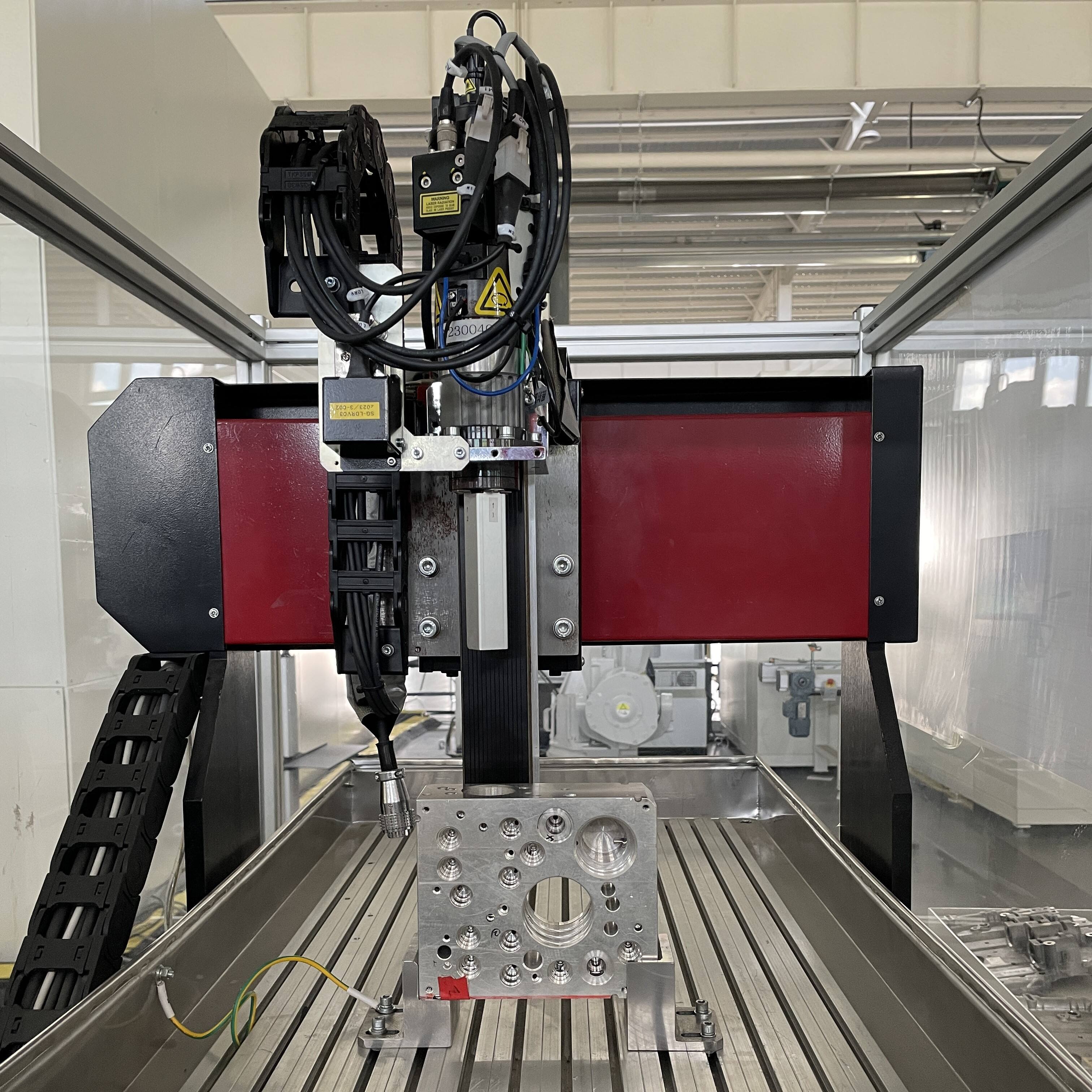

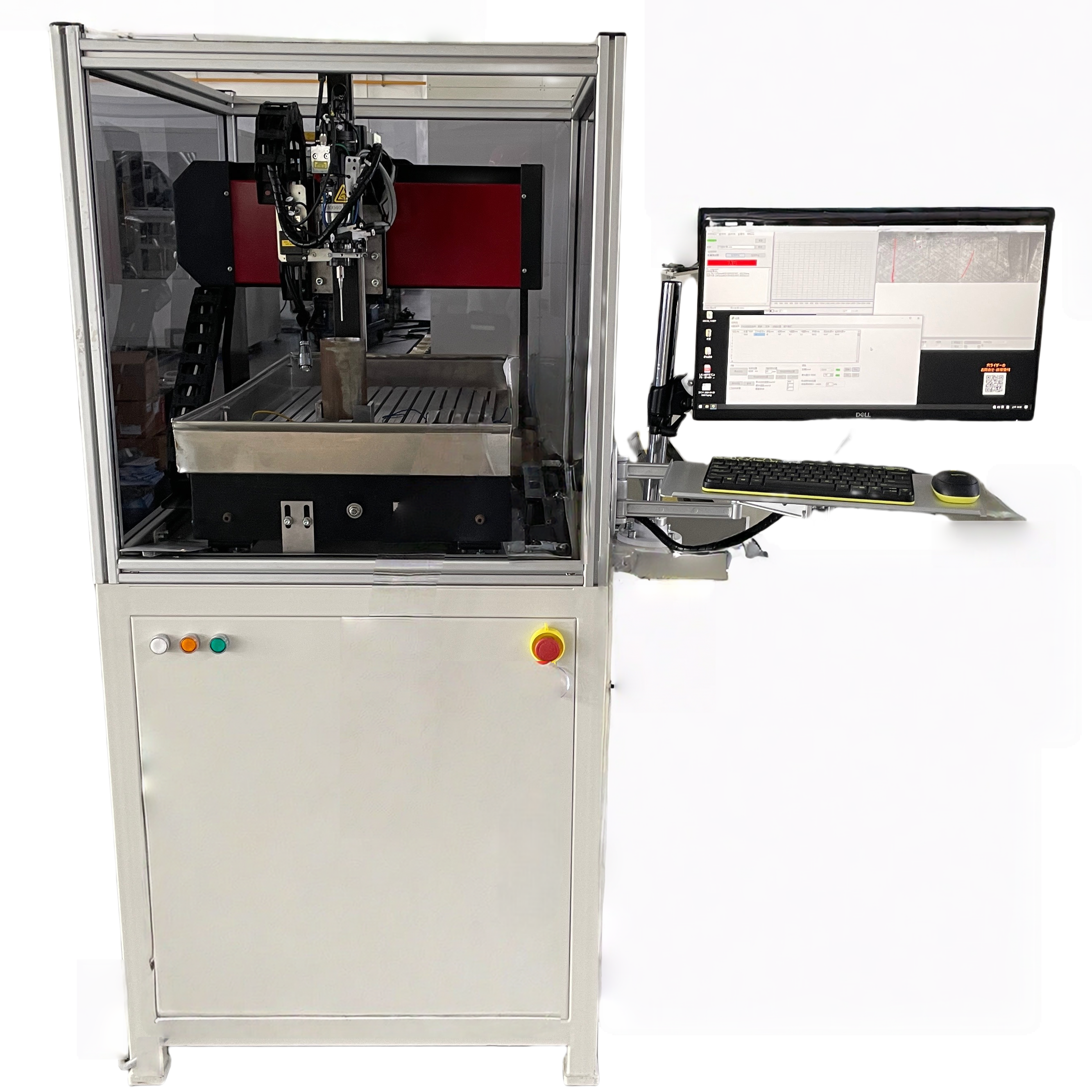

Squire - Hole Inner Wall Defect Inspection System

The Hole Inner Wall Defect Inspection System is designed for high-precision detection of defects such as scratches, bores, and dents inside threaded holes, through-holes, and blind holes. With advanced laser imaging and intelligent algorithms, the system ensures reliable quality control in automotive manufacturing and related industries.

Key Features

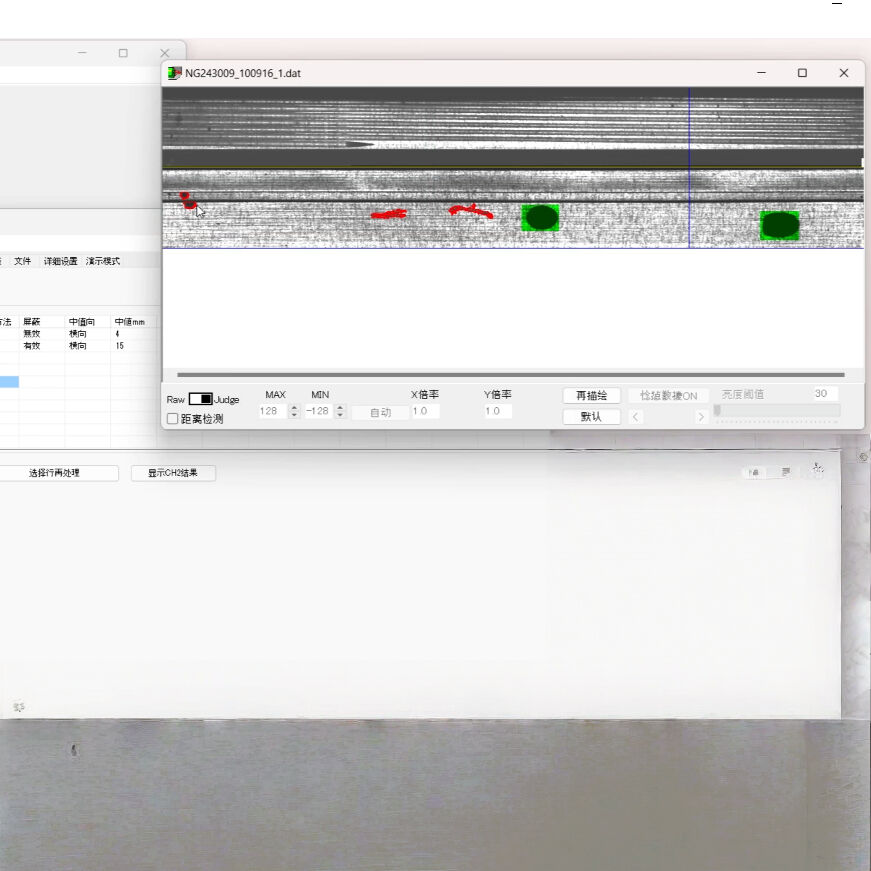

Inspection Capability: Detects inner-wall scratches, pores, and surface defects.

Applicable Industries: Automotive and precision machining.

Workpiece Compatibility: Threaded holes, through-holes, blind holes, and other precision components.

Minimum Detectable Bore Size: φ4 mm.

Detection Accuracy

| Specification Item |

Details |

| Minimum Detectable Defect |

>0.2 mm contour |

| Minimum Resolution |

0.01 mm |

| Production Speed |

25–50 mm/s detection rate |

| Imaging Technology |

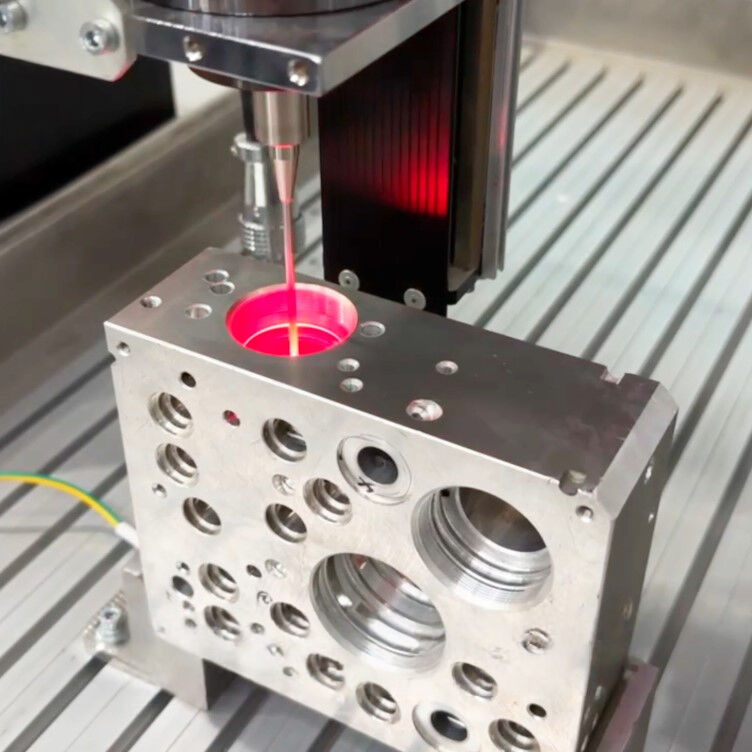

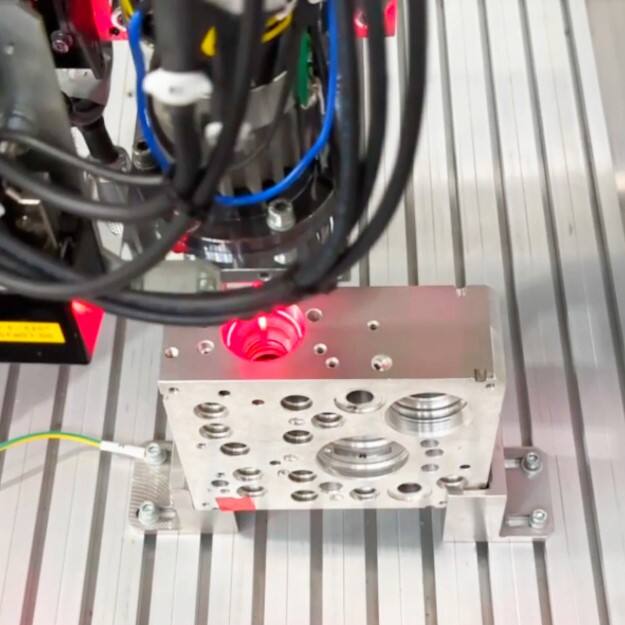

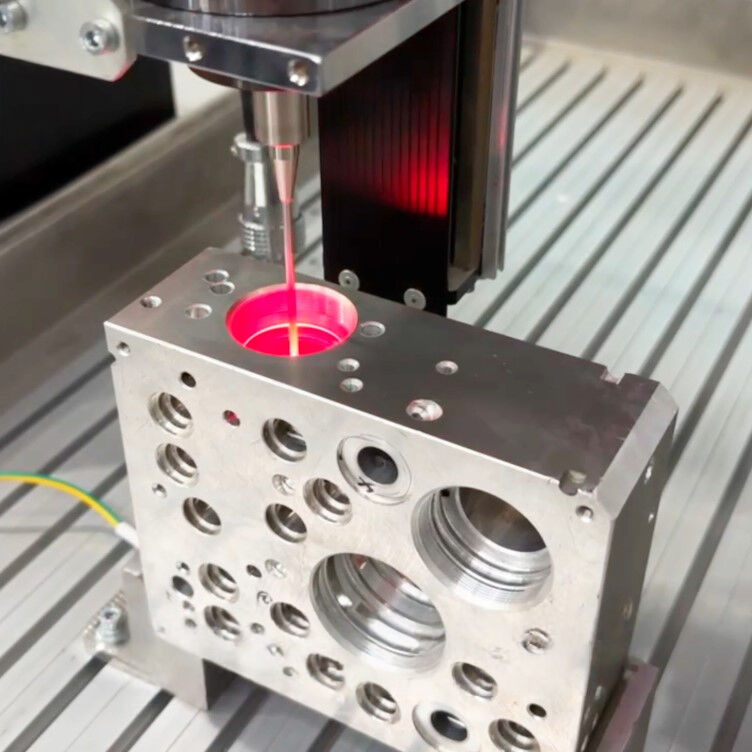

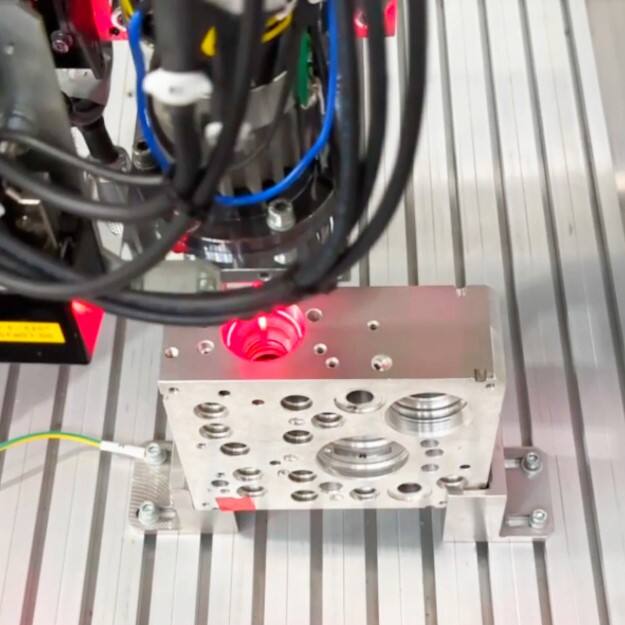

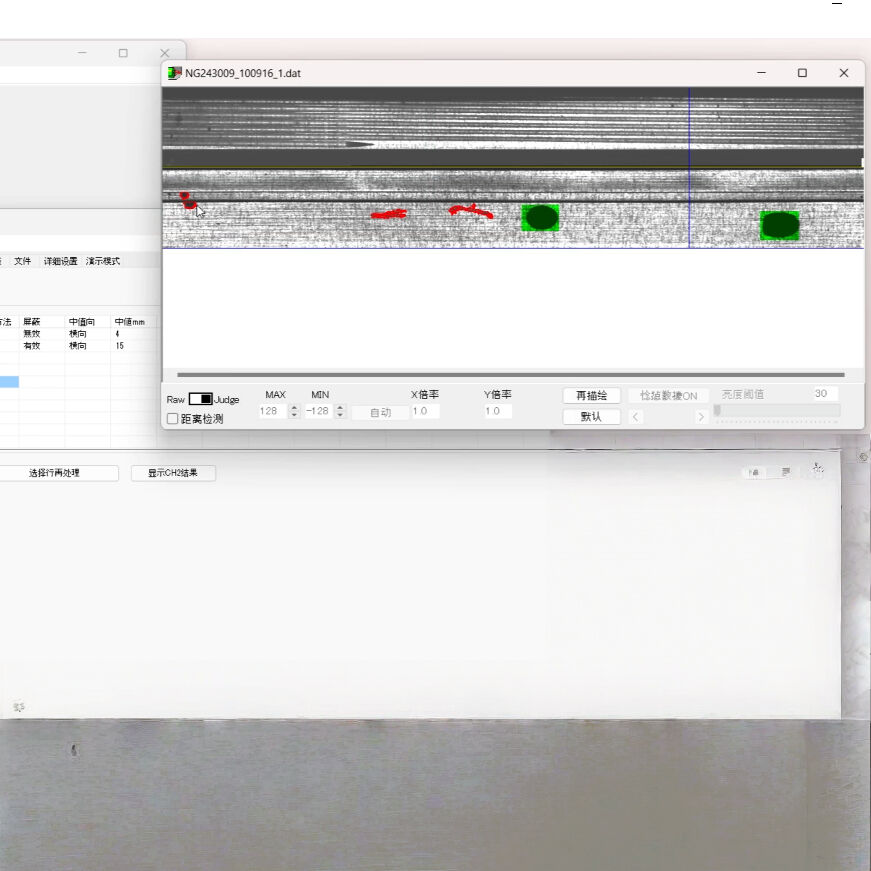

High-speed laser imaging (with red semiconductor laser light source) |

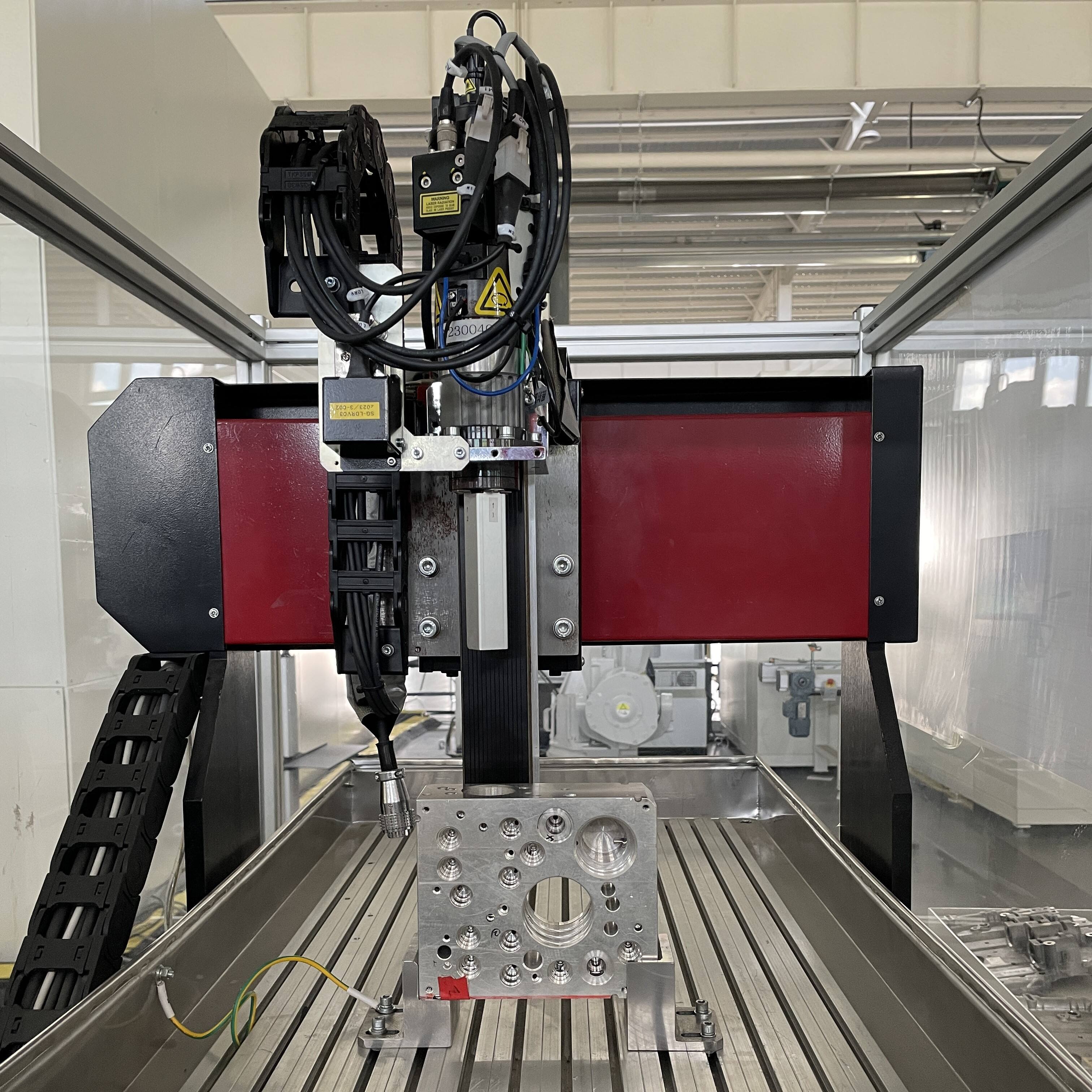

| Transmission System |

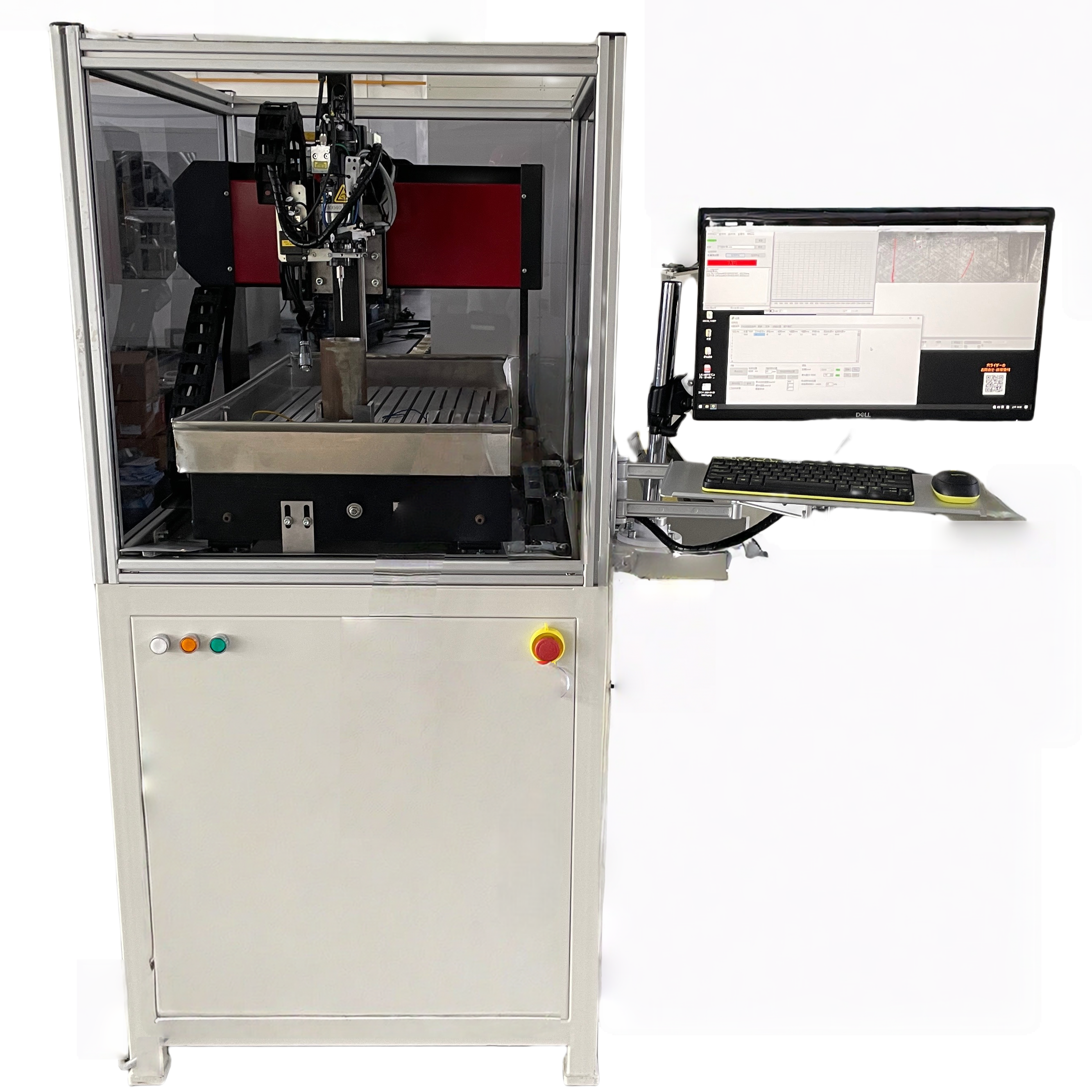

Robotic form with dual-axis servo system |

| Control System |

Industrial PC + PLC |

Advantages

High-Speed Precision: A high-speed rotating laser lens (12,000 rpm) enables accurate detection of fine defects, even in narrow bores as small as φ4 mm.

Superior Imaging: Laser imaging replaces traditional light sources, ensuring clear and stable results with minimal interference.

Flexible Applications:

Supports robot-mounted probes and machining center integration.

Detects diverse components including valve bodies, engine blocks, sleeves, motor cores, housings, and more.

Customizable Design: Available in multiple models, covering bore sizes from φ4 mm to φ120 mm, with full non-standard customization options.

Why Choose This System?

This system provides exceptional defect detection accuracy, strong resistance to light interference, and broad adaptability to various component types. It is an essential solution for manufacturers seeking higher quality assurance, reduced rework, and improved production efficiency.