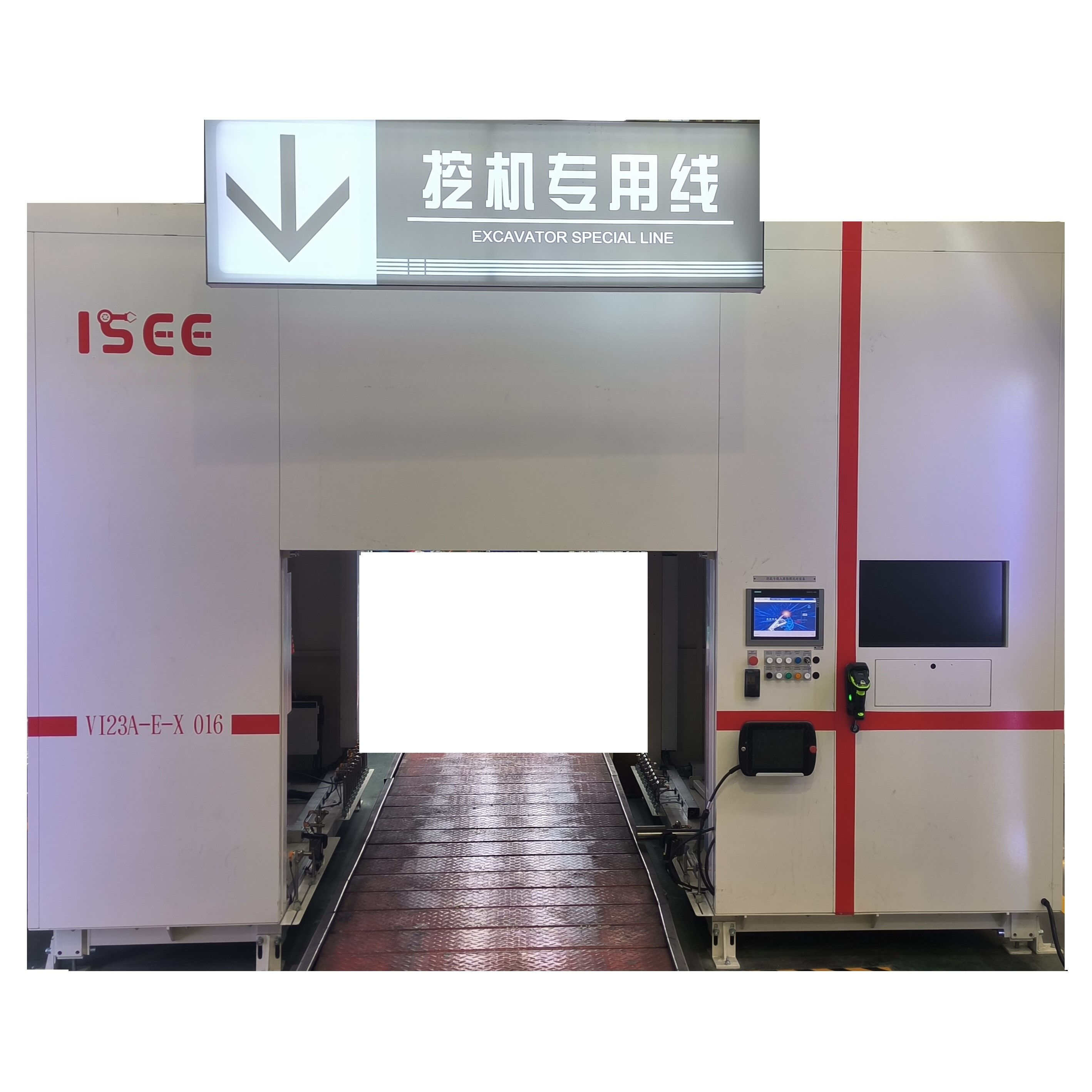

All See Series – Engine Final Assembly Inspection System

- Cycle Time: 60 seconds (customizable per workpiece)

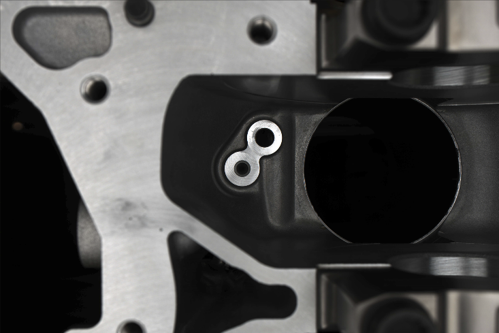

- Industrial Camera: 20-megapixel resolution

- Lighting System: Extra-large high-brightness light source / high-bright strip light combination

- Detection Accuracy: 99%

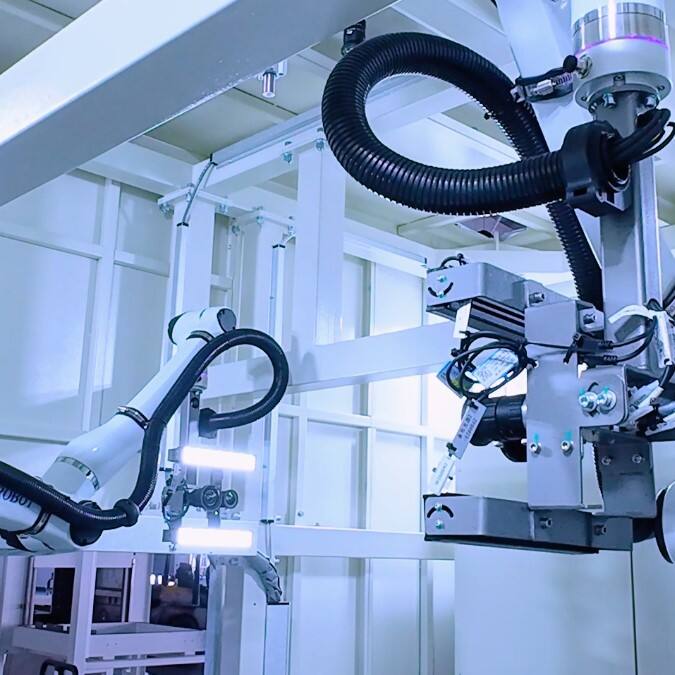

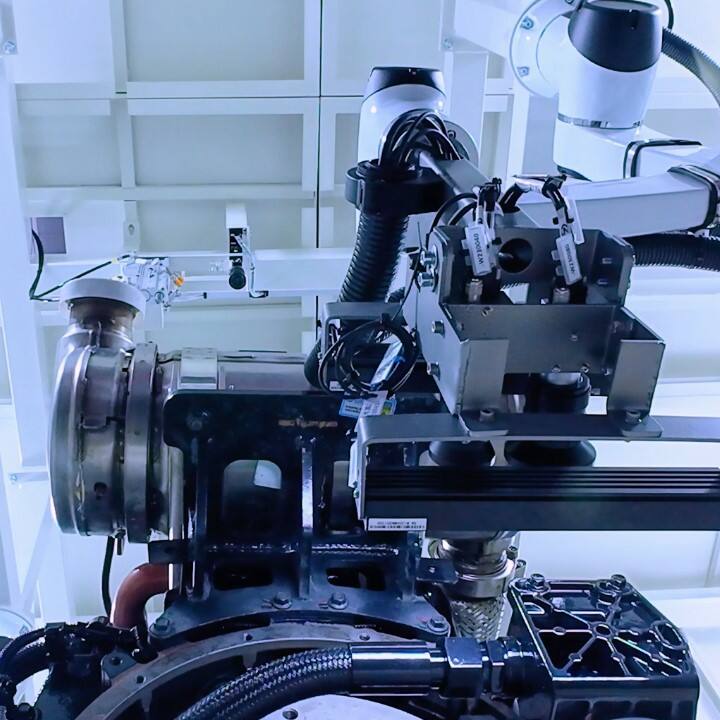

- Robotics Options: FANUC, ABB, KUKA, Yaskawa, Siasun, and others

- Control System: Siemens, Mitsubishi, and others

Description

Overview

The Doctor Series Final Assembly Inspection System is designed to perform comprehensive quality checks before engines enter storage. It automatically photographs each engine, identifies potential misassembles or missing components at designated points, compares part numbers, and creates an archival database to support query and traceability functions.

The Doctor Series Final Assembly Inspection System is designed to perform comprehensive quality checks before engines enter storage. It automatically photographs each engine, identifies potential misassembles or missing components at designated points, compares part numbers, and creates an archival database to support query and traceability functions.

Technical Specifications

| Cycle Time | 60 seconds (customizable per workpiece) |

| Industrial Camera | 20-megapixel resolution |

| Lighting System | Extra-large high-brightness light source / high-bright strip light combination |

| Detection Accuracy | 99% |

| Robotics Options | FANUC, ABB, KUKA, Yaskawa, Siasun, and others |

| Control system | Siemens, Mitsubishi, and others |

*The above product parameters are for reference only

Applicable Industries

Ideal for use in commercial vehicles, passenger vehicles—including new energy vehicles—and related manufacturing sectors.

Compatible Workpieces

● Diesel engine assemblies

● Gasoline engine assemblies

● Transmission assemblies

● Other automotive powertrain units

Process Flow

1.Code Reading – Automatically scans and records part identification codes.

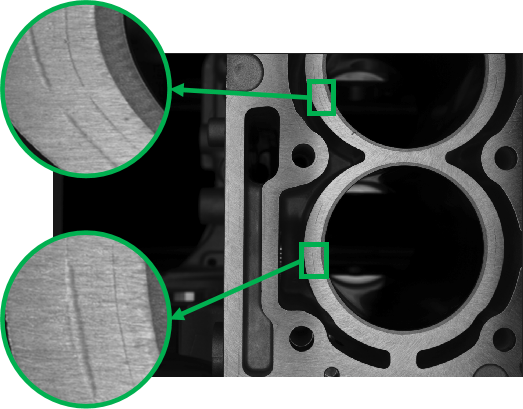

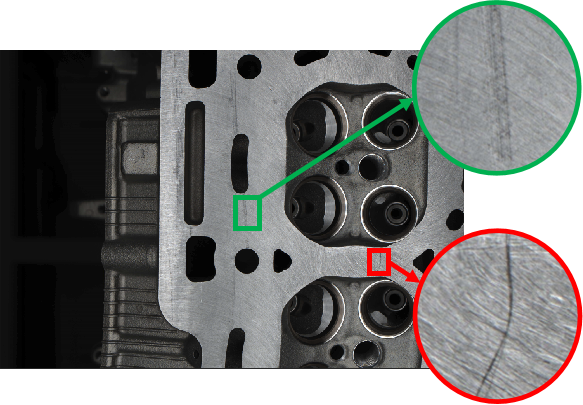

2.Machine Vision Inspection: Detects assembly errors and missing parts, while capturing high-resolution images for record keeping.

For NG Cases:

Manual Re-Inspection – Ensures additional quality assurance.

Traceability – Links inspection data to the product archive for future reference.

Error Analysis – Generates reports for misassemble and omission analysis.