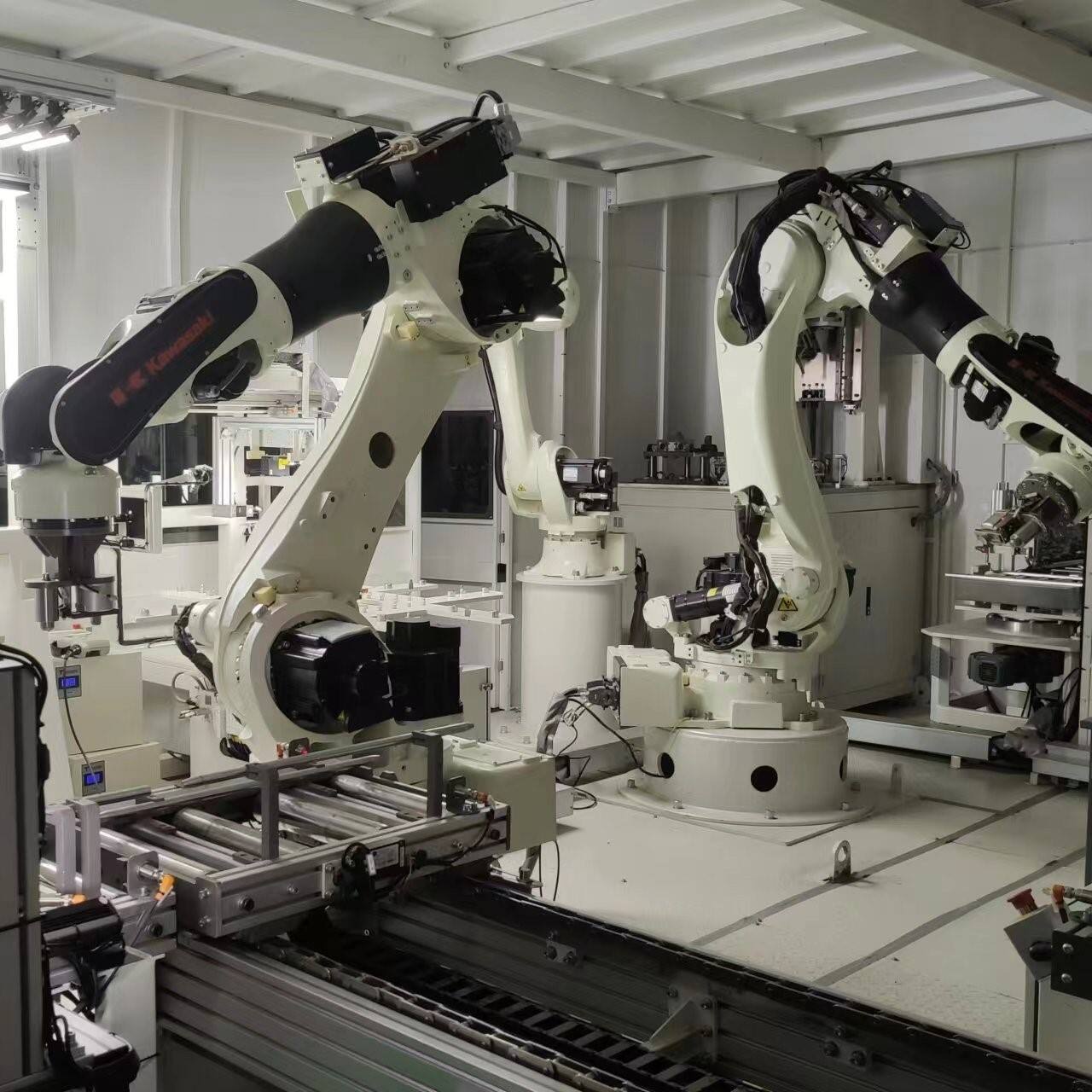

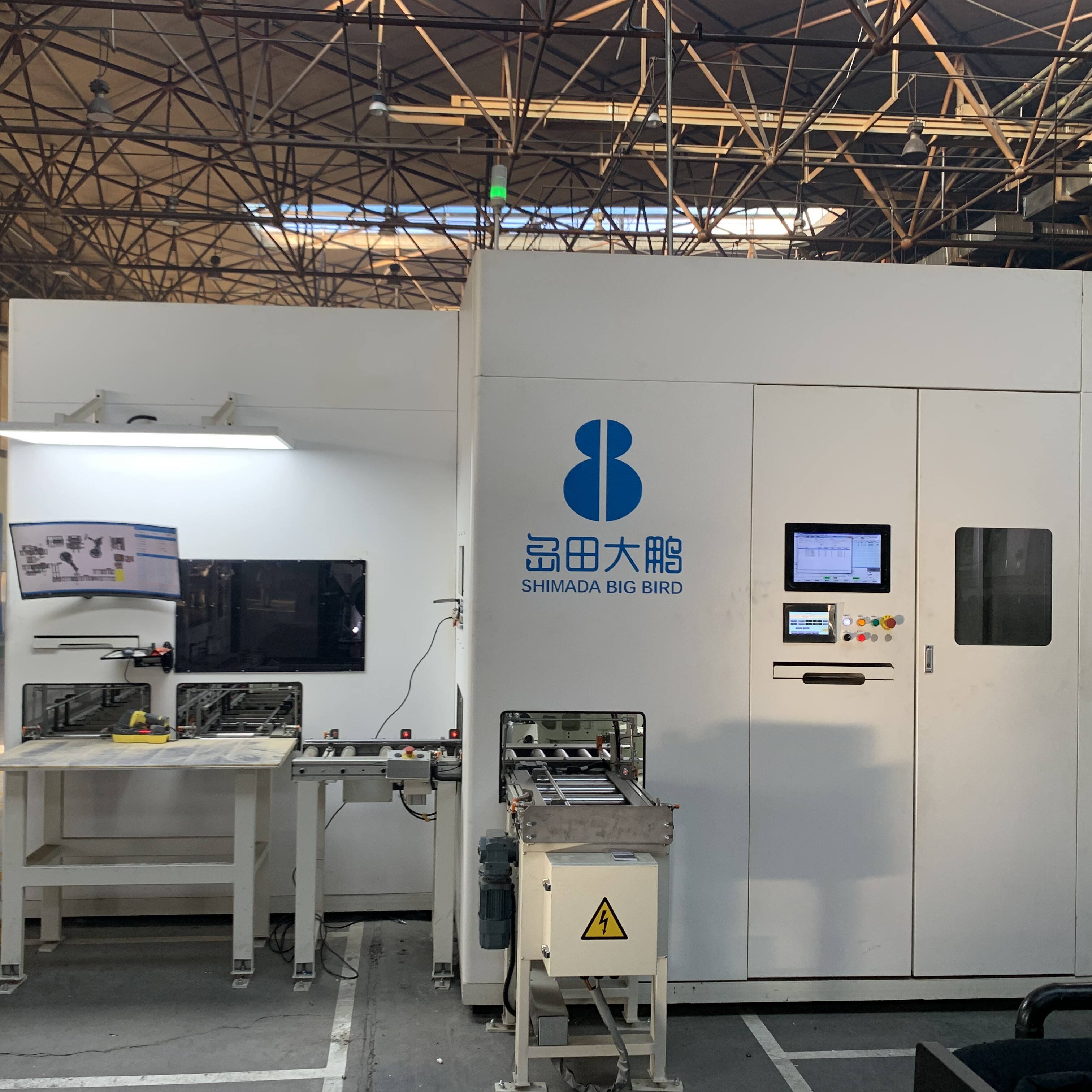

Visual automation detection system for cylinder head defects

Multi variety cylinder head automatic recognition, coding, key dimension detection, defect detection, qualified marking, information binding and storage, replacing manual inspection, improving the automation level of production, and reducing labor costs and missed inspection rates.

Description

Applicable Industries

Commercial vehicles, passenger vehicles (including new energy vehicles), etc.

Corresponding Workpieces

Engine cylinder heads

Process Description

Combustion chamber deburring, identification & coding, defect inspection of cover and intake surfaces, 3D dimension detection, defect inspection of combustion chamber & exhaust surfaces, defect inspection of front and rear ends, machining dimension detection, manual re-inspection.

Defect inspection of machined and rough surfaces

Sand holes, pores, sand blocks, broken cores, wrong boxes, smoke, bumps, scratches, etc.

Dimensional Measurement

Indirect measurement of combustion chamber and intake/exhaust port volumes.

Equipment Specifications

| Production Rhythm | 36 seconds (customizable according to workpiece conditions) |

| Industrial Cameras | 5-25 million pixels (48 units) |

| Light Sources | Surface light, combined strip light |

| Control System | Industrial computer, PLC |

| Laser Profiler | Detection accuracy ±0.1mm |

*The above product parameters are for reference only. For details, please contact us by phone.