Knight - Paint Surface Inspection System

The Paint Surface Inspection System provides high-precision, automated detection of vehicle body paint surfaces across all colors, all within a single production cycle. Powered by advanced robotic guidance, the system achieves metrology-level accuracy, ensuring objective and consistent inspection results while eliminating human error.

By reducing reliance on manual inspection, manufacturers can lower production costs, while reliable statistical data helps optimize processes and improve efficiency. Integrated marking robots precisely indicate defect locations, greatly simplifying rework and repair. In the future, this technology can be extended to enable fully automated defect repair guided by robots.

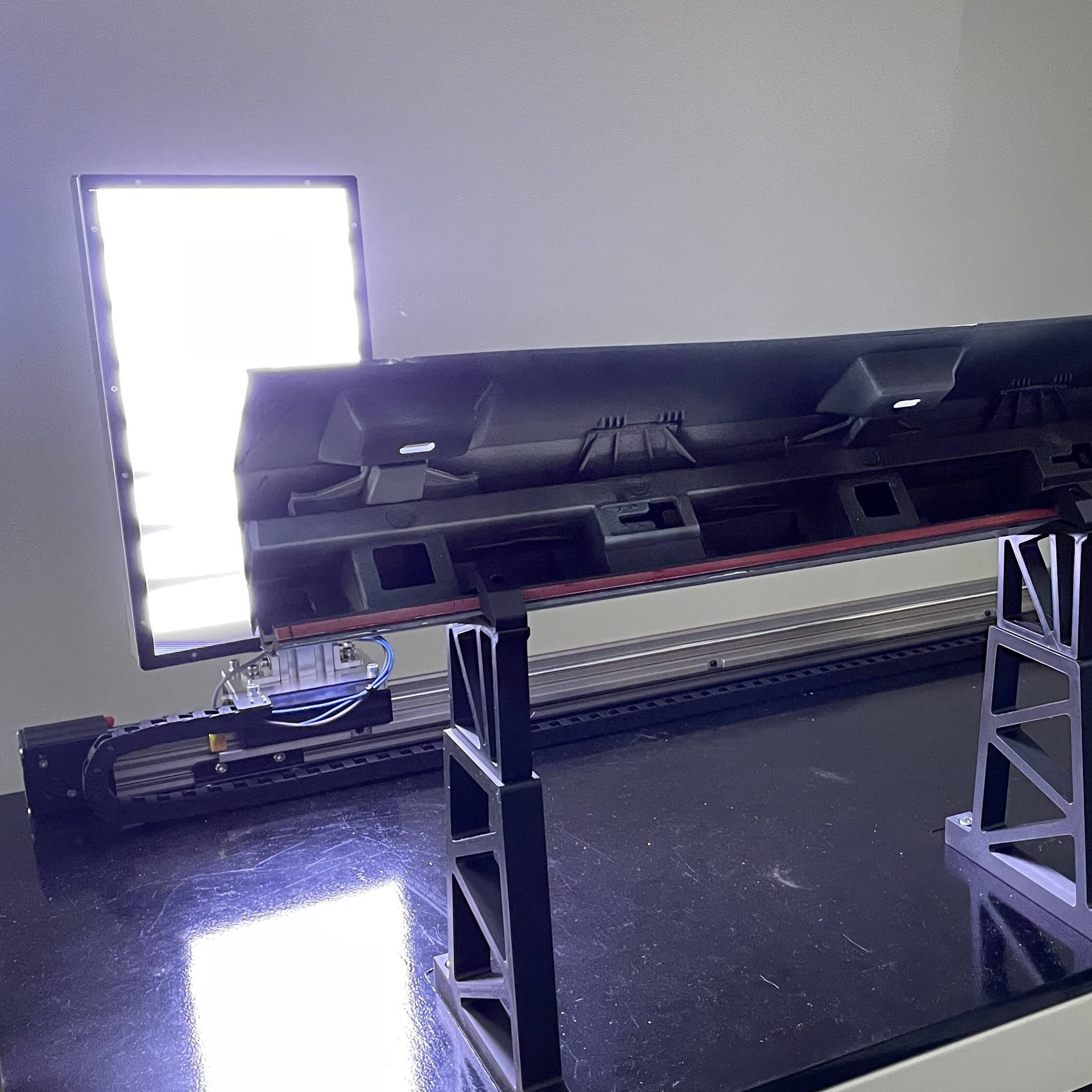

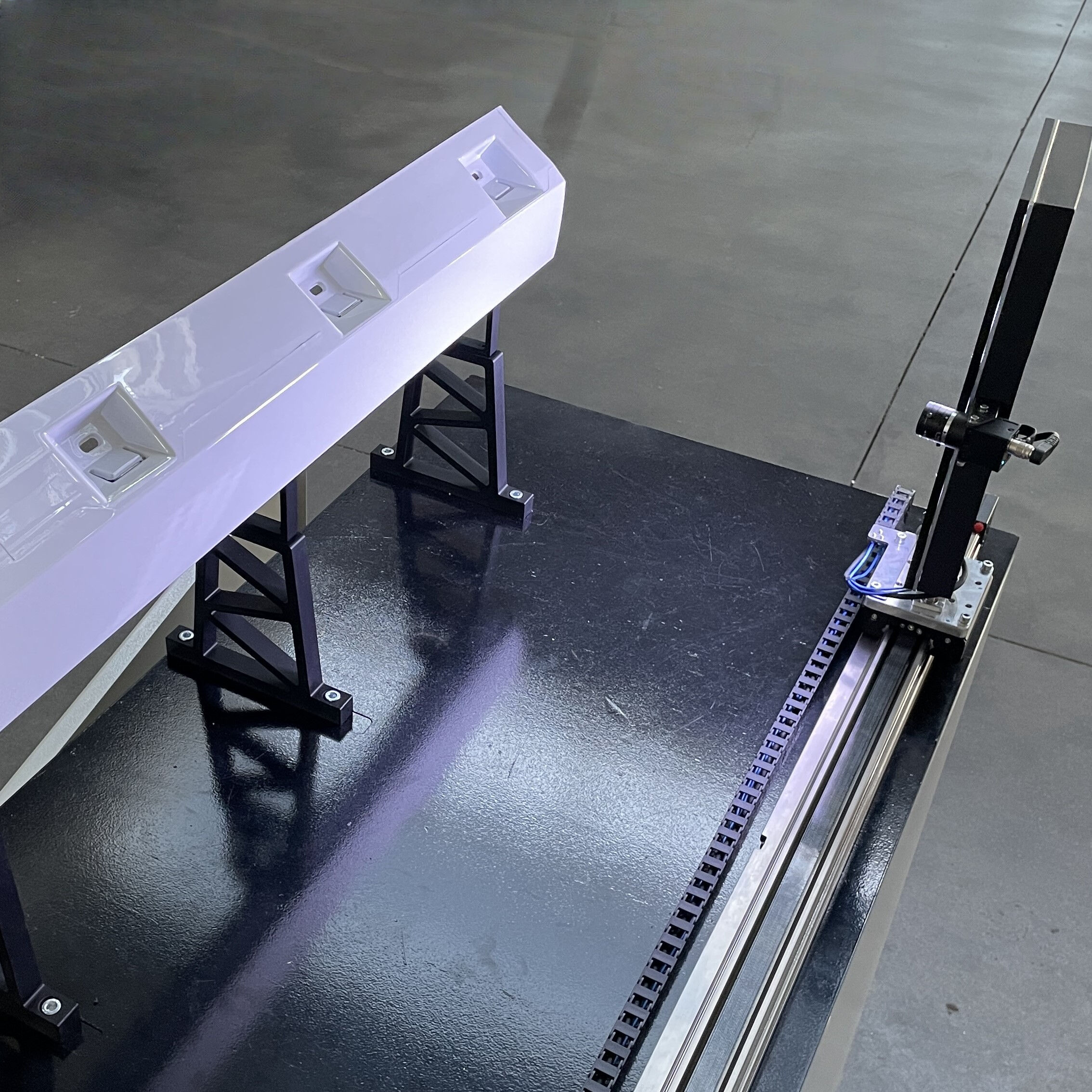

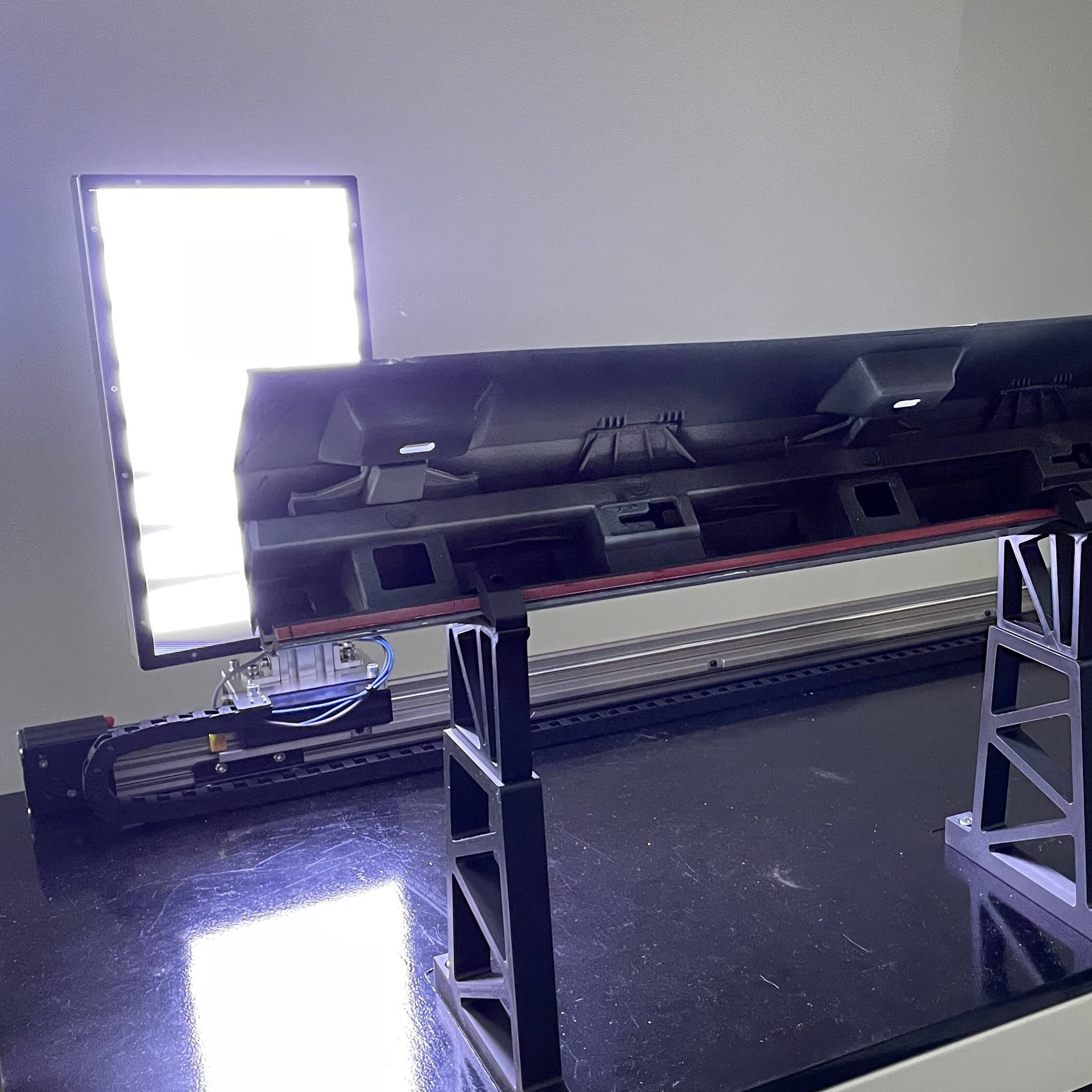

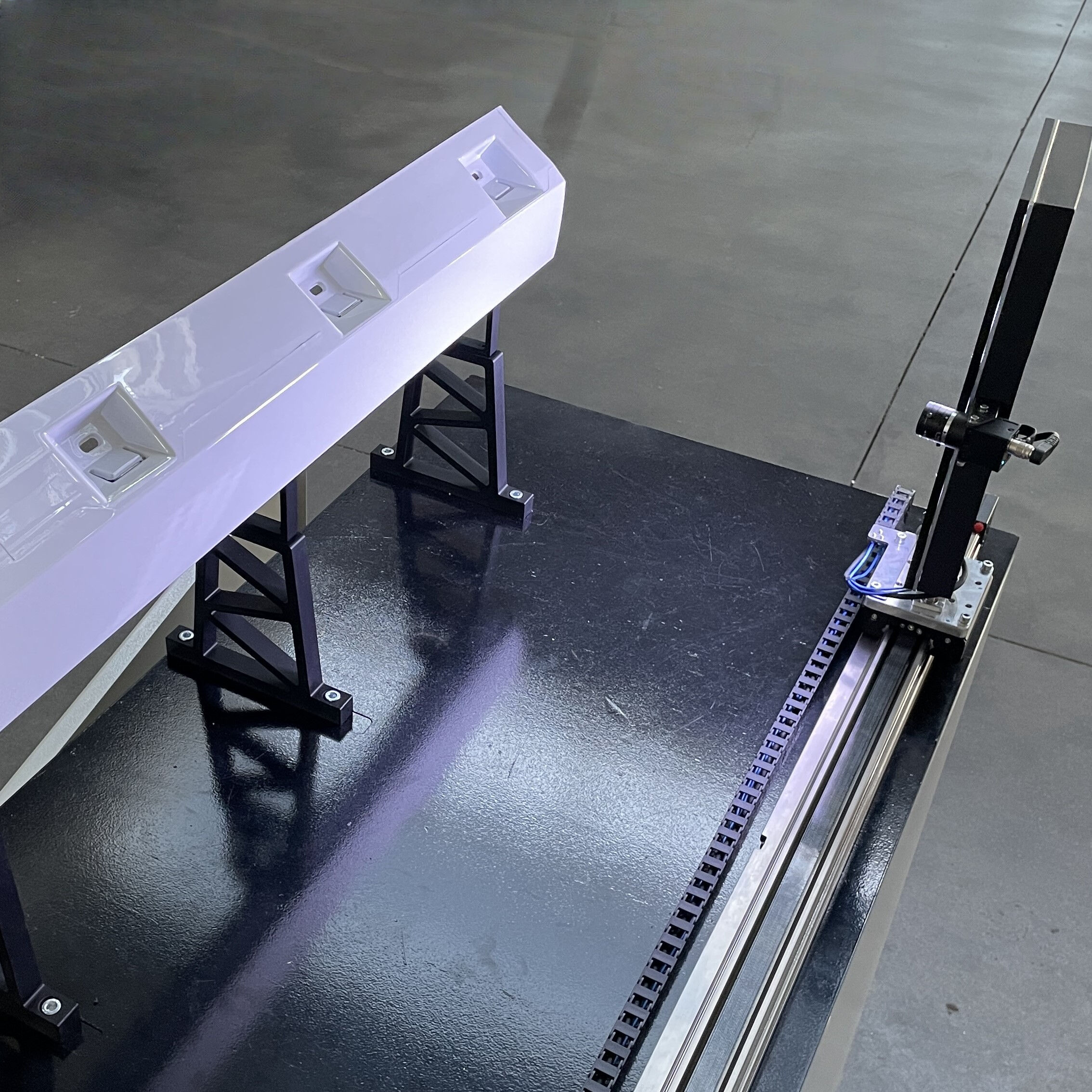

PAINTSCAN – Hybrid Technology

The PAINTSCAN system integrates two surface inspection methods into one sensor through an embedded module, enabling comprehensive and efficient defect detection.

LED matrix monitor with dedicated illumination modes

Diffuse lighting with high optical sensitivity

High-resolution digital camera with fast acquisition speed (200 Hz)

Direct camera-to-embedded computer connection

Detects all surface defects, both shape-related and non-shape-related

Multi-image verification (up to 10 images per location)

Inspection Modes:

Line Tracking (continuous scanning)

Stop-and-Go (step-by-step scanning)

Full Vehicle Inspection Time:

50–70 seconds with 4 robots (depending on surface area)

<40–60 seconds with advanced 7-axis robots

Automated Marking System

Paint defects are located using a visual coordinate system within the car body reference frame.

The marking system generates dynamic marking trajectories with collision avoidance checks.

Each defect is marked in about 3 seconds, including robot movement time.

Compatible with all major robot brands.

This system represents a new standard in paint surface quality assurance—delivering accuracy, efficiency, and cost savings while paving the way for future automated defect repair.