Orient See - Hole Position Inspection System

Online Vision Inspection System for Complex Structural Parts

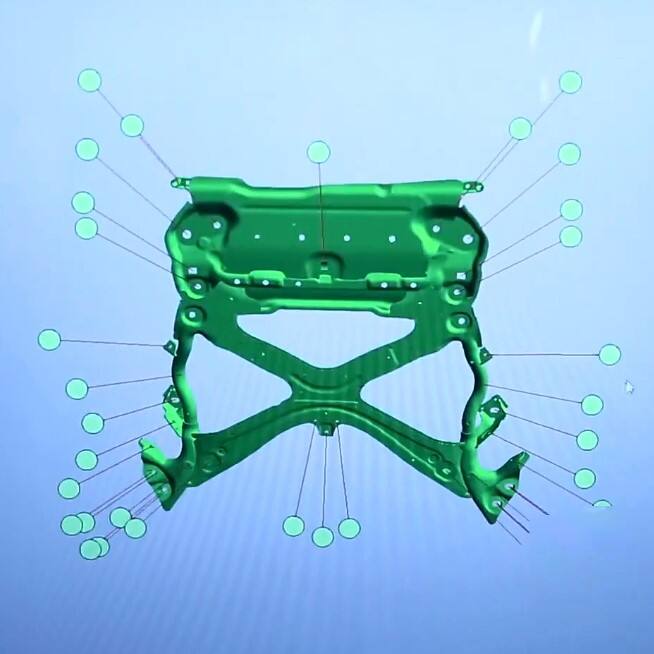

The Online Vision Inspection System for Complex Structural Parts is designed to ensure precise, automated quality control of irregular-shaped components in automotive and industrial applications. With advanced multi-camera technology and intelligent analysis, the system guarantees reliable defect detection and accurate dimensional verification, helping manufacturers achieve higher efficiency and quality consistency.

Description

Guardian - Hole Position Inspection System

Online Vision Inspection System for Complex Structural Parts

The Online Vision Inspection System for Complex Structural Parts is designed to ensure precise, automated quality control of irregular-shaped components in automotive and industrial applications. With advanced multi-camera technology and intelligent analysis, the system guarantees reliable defect detection and accurate dimensional verification, helping manufacturers achieve higher efficiency and quality consistency.

Performance Highlights

| Specification Item | Details |

|---|---|

| Repeatability | ±0.02 mm |

| Correlation with CMM | ±0.1 mm |

| Unified Coordinate System | Ensures consistency across the entire measurement range |

| Flexible Adaptation | Supports quick switching for different models |

| Inspection Time | 10–30 seconds per workpiece |

Inspection Capabilities

Screw presence and absence detection

Slot position verification

Gap distance measurement

Hole position accuracy check

Nut presence and absence detection

Multi-Camera System

Redundancy Design: Multiple cameras capture the same point; single-camera failure does not affect inspection accuracy.

Enhanced Precision: Each feature point observed by multiple cameras, with accuracy improving as the number of cameras increases.

Statistical Reporting: One-click automated report generation enables quick analysis, reducing process adjustment time significantly.

|

|

Why Choose This System?

With high accuracy, fast inspection speed, and robust reliability, this vision inspection system is an ideal solution for manufacturers seeking to enhance product quality while reducing time cost and labor dependency.