News

How to Select the Right Visual Inspection Equipment for Auto Parts?

Keep in Mind Key Technical Advantages

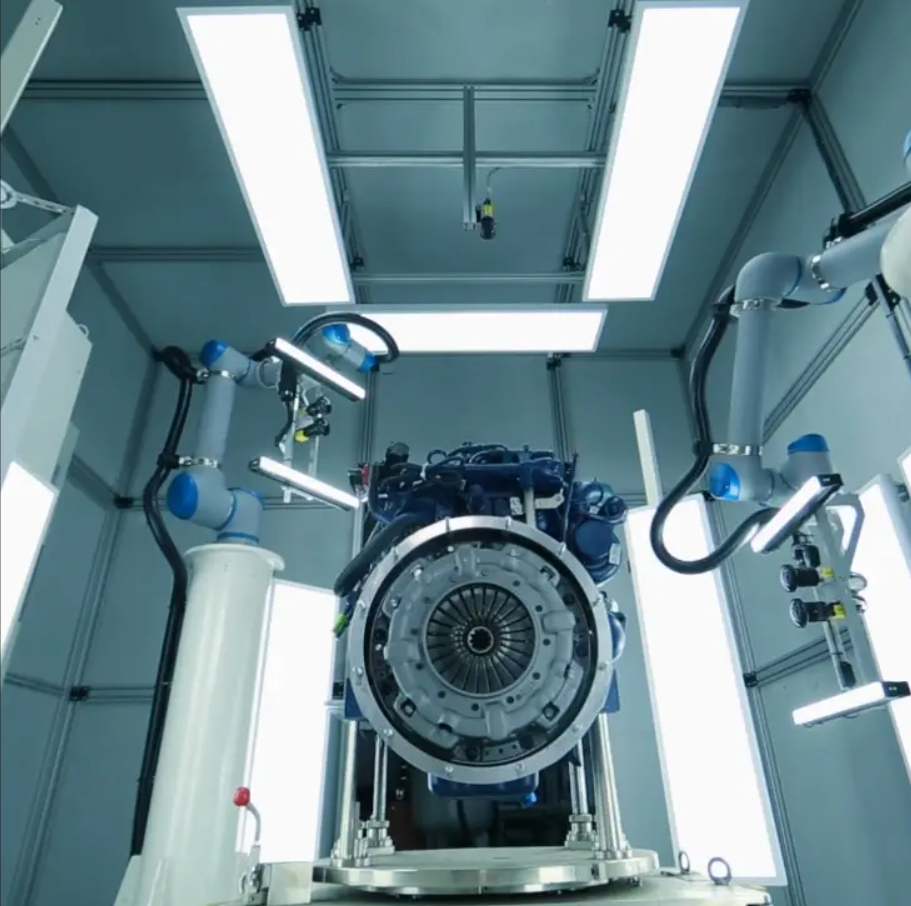

When selecting visual inspection devices for automotive components, the fundamental consideration should be core technical performance to ensure good quality. Equipments that provide high quality imaging and have intelligent analysis features should be prioritized because that can help in the accurate identification of minor defects such as surface scratches and other deviations in important parts, for example engine and transmission systems. Advanced machine capabilities should be the ideal combination of good vision technology as they can adjust to different part materials and complex shaped inspec and lose no speed. These technical features help in minimizing the chances of missed detection and provide confidence for the equipment to be used for stable operation in the long run to avoid high maintenance and replacement costs.

Assess Compatibility with Real-life Scenarios

When it comes to auto parts, there are many different types and specific selections. Therefore, the devices must align with specific production scenarios. Consider the equipment's ability to adapt to different sizes of parts, including small fasteners, as well as large structural pieces, and whether it has flexible adjustments to suit varying speeds in the production lines. For example, equipment that works well with the automated assembly lines will increase overall production efficiency, as will equipment that allows customization of varying inspection parameters to fulfill the specific needs of different manufacturing processes. If factories ignore the compatibility of their equipment with the production scenarios, their automated inspection and other pieces will end up being either inefficient for the tasks, or even blind, and result in negative ROI, regardless of the equipment's purchase price.

Finding the Right Balance Between Performance and Cost

Cost-effectiveness is an important aspect when it comes to the equipment providing the highest ROI. Cost is not about balance in equipment for it to be the best available in price, but in purchasing equipment balanced in price, and having as much equipment performance as possible. Quality equipment costs are not always the highest. The lowest priced equipment is not always the best equipment in terms of performance. The better the performance to price ratio, the better the equipment is. For certain equipment, the cost is price plus low ongoing costs due to efficient designs that are either energy saving in operation and or reduce labor needs, with better algorithms. When priced equipment is compared to other price equipment, cost effective prducts deliver better results. Cost effective equipment and other purchase equipment performs better beyond short term needs of the factory and deliver results beyond just short term savings.

Check Quality and Reliability

The quality and reliability of equipment suggest how it can hold up to the industrial production environment. Equipment that can withstand abrasion and continuous workloads and can operate in dusty conditions or extreme temperatures is critical. Make quality assessments and documentation, and check other automotive manufacturers for their feedback to evaluate quality in practice to avoid the risk of frustration. Quality equipment translates to minimum downtime and malfunctioning at critical monitoring processes, therefore affecting production and product quality.

Evaluate Non-Technical Post- Sales Support and Auxiliary Services

Value is exacerbated by the lack of consideration for professional support services post sale. Prefer suppliers who provide prompt support, regular reminders to perform maintenance, and notifications of software updates. In the case of downtime losses due to system malfunction, or adjusted processes, responsive support can help avoid losses. Process guidance for inspection from highly qualified suppliers is also useful to assist in optimizing the use of the equipment. Value throughout the equipment’s life adds to the cost effectiveness of the service provided.

Objectives of Business Value and Long Term Development

It isn't enough to simply consider if the right visual inspection systems solves an immediate issue and detect problems from the start. It is just as valuable to consider how the system can help the long term growth of the business. Determine how the systems help provide an improvement to the quality of the product and an enhancement to the brand. Trust and reputation from customers are earned; systems that provide detailed inspection data help eliminate production bottleneck slowdowns; optimization of the processes and less waste is always a positive. If a manufacturer is aiming to be a global player in their industry, it is paramount that inspection systems are easily aligned to global standards. Pairing the goals of a business with the right systems will convert the purchase of equipment to an investment in sustainable development.