News

How to Achieve Efficient Deburring for Metal Components?

Efficient Procedure in Deburring of Metal Components

Deburring can make or break the performance, assembly, and longevity of products in the metal components manufacturing industry. The appropriate method and equipment for deburring will maximize production efficiencies while maintaining quality. The following are professional observations and practical ways to get the most from deburring, specifically for the three most common technologies used in the industry.

Brush deburring: gentle, with even surface finish

For deburring metal components surface finishing where the base material cannot get damaged, brush deburring is the preferred method. Controlled surface contact with specialized abuse or nylon, steel wire, or other brush filament materials removes burrs.

This method is exceptional for detailed shaped and complex components such as precision, gears, and shafts. Narrow gaps and other difficult to reach surface areas are accessed by the flexible brushes. Because brush deburring uniformly finishes surfaces, the results typically eliminate secondary polishing steps.

Other key traits are very slight material loss, less than other methods, dependable results across batches, and the method works with most metals including copper alloys, steel, and aluminum. This method works best for automotive parts and other electronic components where surface integrity is important.

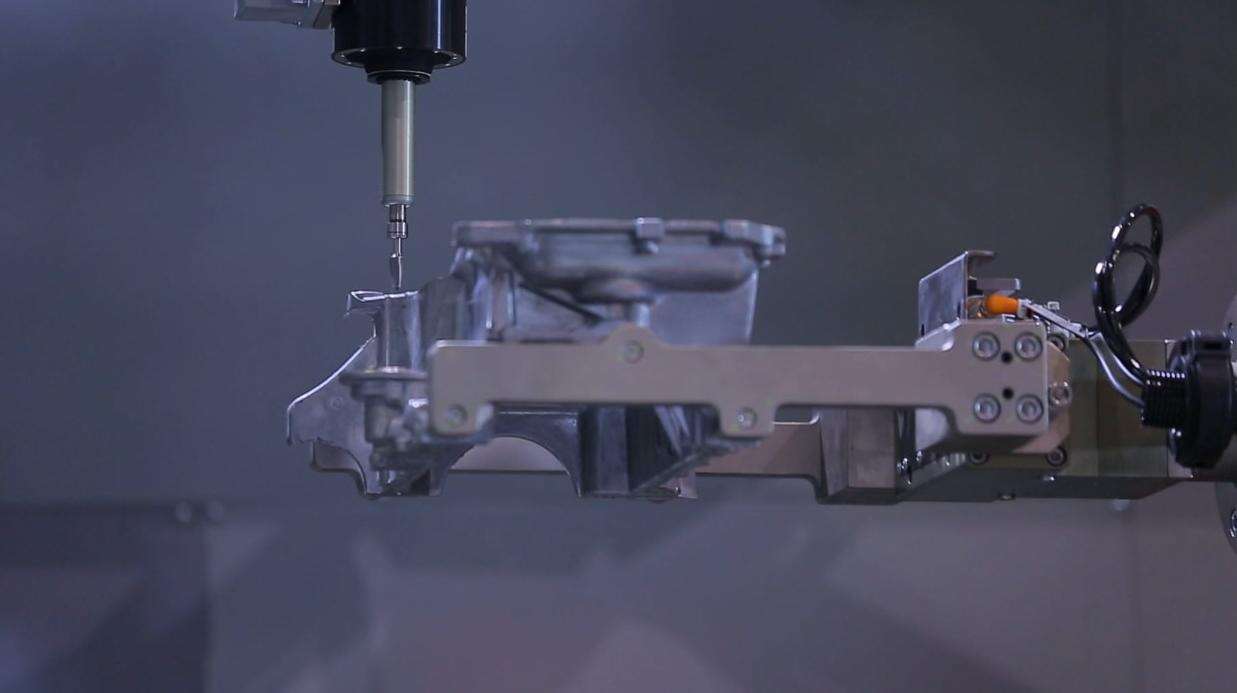

Tool Deburring: Precision for Targeted Burr Removal

Tool deburring uses specially designed cutting tools to remove burrs one at a time using high accuracy. This approach is best for parts with tough burrs or very tight tolerances.

Tools customized to each part design allow for burrs to be removed precisely at edges, holes, and surfaces that mate. Compared to manual deburring, tool systems eliminate human error and improve repeatability for less variation in the process. This is very beneficial is used for mass production of parts with high consistency and speed requirements.

Examples of tough parts with high volume production that benefit are engine blocks, crankshafts, and camshafts. This method allows full integration into automated production lines, improving overall cycle times while keeping the part robust.

High Pressure Water Deburring: Efficient and Eco Friendly Solution

High pressure water deburring uses jets of water at extremely high pressure to remove burrs and other contaminants within the part. It is efficient and eco-friendly because it usually uses water-based cleaning agents that are harmless to the environment, unlike many cleaning agents.

The rapid water streams are able to penetrate even the most complex shapes, which makes it perfect for parts that contain internal channels or are hiding some burrs. It works exceedingly well for high volume production environments because this method has high operational speeds. Moreover, this method does not create mechanical stresses on the parts which lets the part keep its properties unchanged.

For example, the method is used for deburring parts of transmissions, hydraulic systems and components of fuel systems in the automotive industry. Moreover, it allows for easier waste management and is less harmful to the environment because it is a water based system, which makes it compatible with sustainable manufacturing.

There are several broad factors that need to be considered when choosing a deburring method. This includes material of the part, intricacies in its design, production targets and expected outcomes. This helps in making sure that specific method is tailored to the needs of the application most efficiently and/or cost effectively.

The performance of advanced deburring systems with smart control systems is even greater than this. These systems incorporate vision inspection systems which are able to detect diagnosis of burrs and modify the process in real-time to improve result consistency. In addition to this, the maintenance of tools and equipment on a regular basis needs to be prioritized in order to keep the systems running efficiently and to minimize the chances of downtime.

Manufacturers can achieve better quality components, lower costs, and drop more competitors with the right combination of brush, tool, and high pressure water deburring technologies. To achieve efficient deburring, the optimal method must be aligned with the specific circumstances of the application.