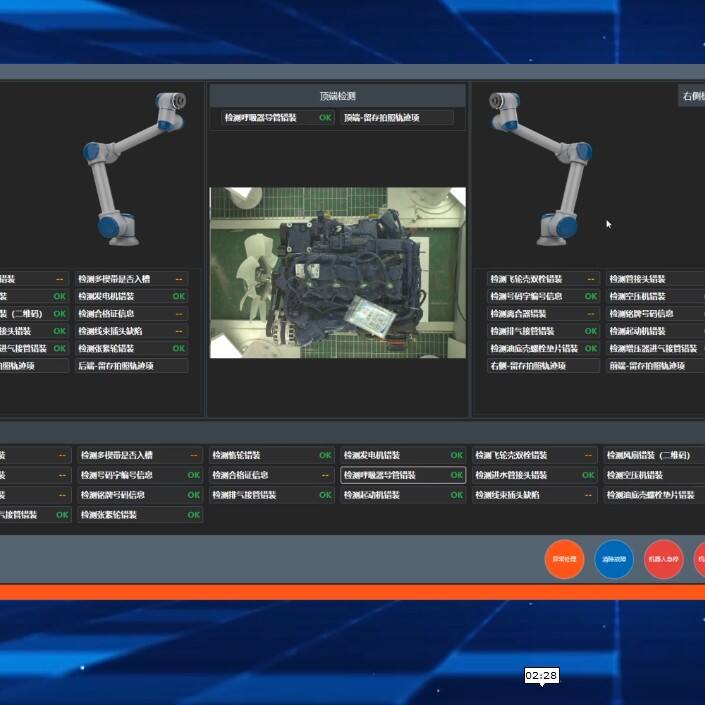

Final Inspection of Doctor Series Engine Assembly2

Production cycle: 70 seconds (customized according to workpiece conditions)

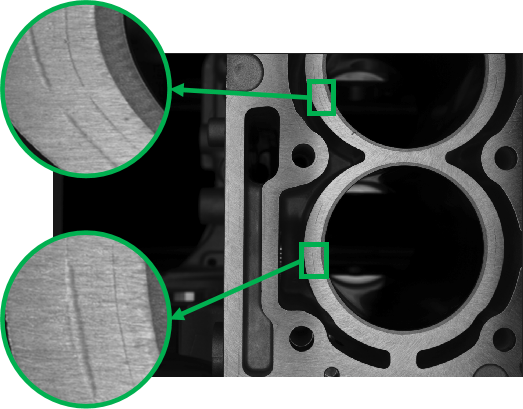

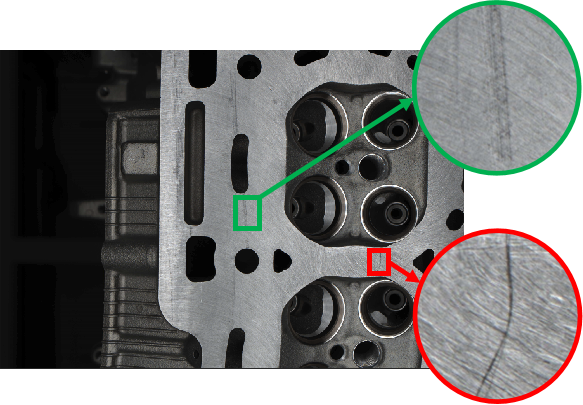

Industrial camera: 20 million pixels

Light source: super large size high-brightness light source/high-brightness bar light combination

Description

Applicable Industries:

Commercial vehicles, passenger vehicles (including new energy), and other fields

Corresponding Workpieces:

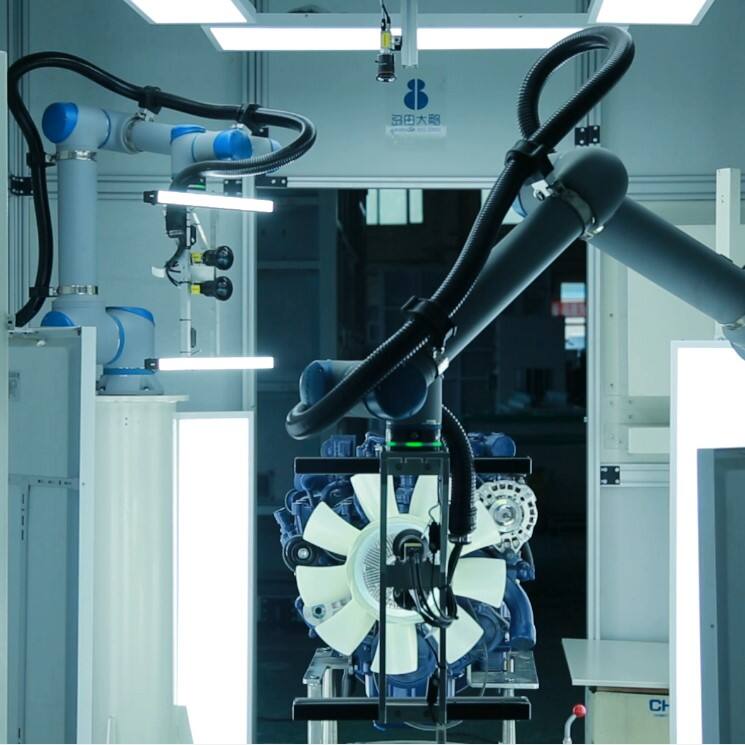

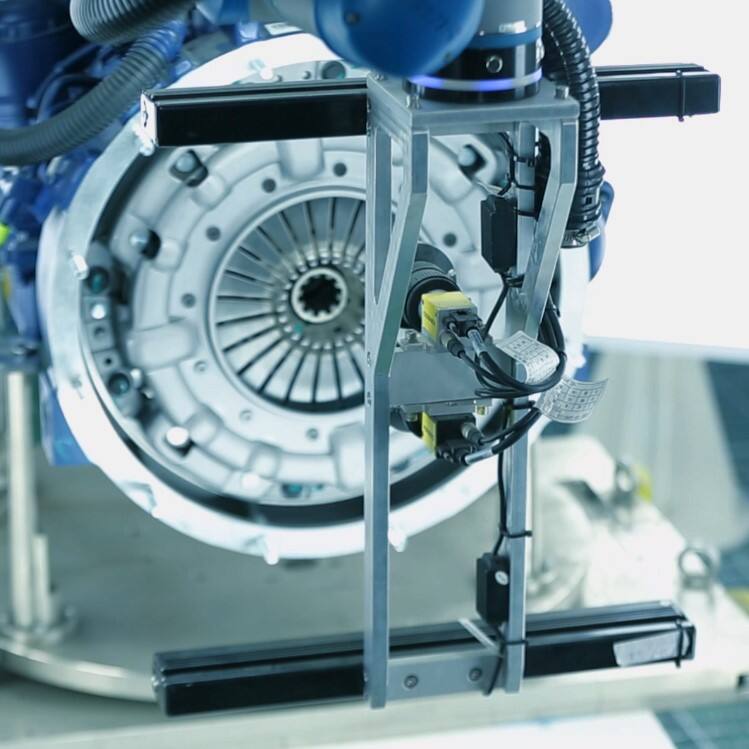

Diesel engine assemblies, gasoline engine assemblies, transmission assemblies and other automotive assembly units

Equipment Type:

Chain plate conveying, robotic type (single robot or multiple robots)

Equipment Description:

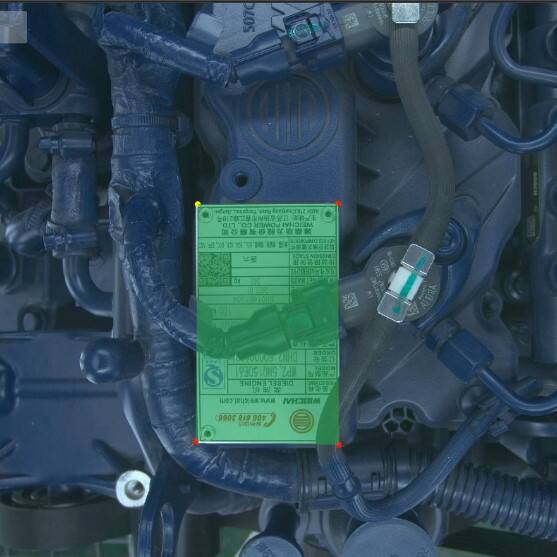

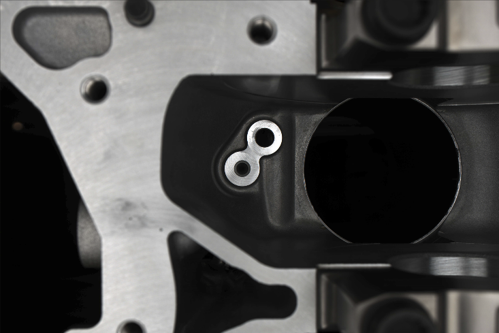

Can be used for batch online inspection of misinstallation and missing installation of components in assembly units (bolts, multi-wedge belts, nameplates, certificates of conformity, fans, filters, etc.)

Process Description:

Code reading, machine vision inspection (component inspection & overall photo retention), manual re-inspection, traceability, misinstallation and missing installation data analysis

Equipment Specifications:

| Production cycle | 70 seconds (customized according to workpiece conditions) |

| Industrial camera | 20 million pixels |

| Light source | Super large size high-brightness light source/high-brightness bar light combination |

| Accuracy rate | 99% |

| Robots | FANUC, ABB, KUKA, Yaskawa, Siasun, Elite, etc. |

| Control system | Siemens, Mitsubishi, Advantech industrial computer |